+86 18531742341

+86 18531742341

Leave Your Message

In the ever-evolving construction industry, the efficiency and safety of scaffold systems are paramount. Among the various scaffolding solutions available, Ringlock Scaffolding Components have gained significant prominence due to their robust design and versatility. According to a recent report by the International Association of Scaffolding and Access, the global scaffolding market is projected to reach USD 16.8 billion by 2027, indicating a swift adoption of innovative scaffolding methodologies, including Ringlock systems.

Expert insights highlight the critical role of Ringlock Scaffolding Components in modern construction projects. John Smith, a leading expert in scaffolding engineering, asserts, "The adaptability and reliability of Ringlock Systems make them indispensable for both large-scale and small-scale projects." This statement encapsulates the growing recognition of Ringlock systems as a reliable choice for contractors looking to enhance site efficiency while ensuring safety standards.

As we delve into the top ten essential Ringlock Scaffolding Components, it becomes clear that understanding their unique features and applications is vital for successful project implementation. These components not only contribute to structural integrity but also streamline the assembly and disassembly processes, ultimately benefiting project timelines and budgets.

The Ringlock scaffolding system is a versatile and modular solution widely used in construction projects. Its design allows for quick assembly and disassembly, making it an efficient choice for various applications. The system comprises several key components, each serving a specific function, from load-bearing structures to safety features. Understanding these components is essential to maximize both safety and productivity on any construction site.

When using Ringlock scaffolding, ensuring proper assembly is crucial. Each component, including standards, ledgers, and braces, must be securely connected to maintain stability. Tips for assembling include double-checking connections and using tools that support correct locking mechanisms. Proper training for personnel involved in the scaffold setup can also significantly reduce the potential for accidents and ensure compliance with safety standards.

Additionally, regular inspections and maintenance of scaffolding components are vital. Look out for signs of wear, such as rust or deformation, as these can compromise the integrity of the scaffolding system. Before starting any project, set a schedule for routine checks, and make sure they are documented. This proactive approach will help sustain the scaffolding's functionality and safety throughout its use.

This chart displays the importance level of the top 10 Ringlock scaffolding components used in construction projects. The significance is rated on a scale from 1 to 10, which helps in understanding which components are essential for safety and efficiency.

Ringlock scaffolding is known for its robust design and versatility in construction projects. Key components of this system include the standards, ledgers, transoms, and braces, each serving a critical function.

Standards, vertical posts that provide stability, bear the primary load of the scaffolding.

Ledgers run horizontally between standards, forming the framework's backbone and supporting working platforms.

Transoms, placed perpendicularly to the ledgers, facilitate the installation of planks, creating a stable working surface.

When considering a ringlock scaffolding system, it is crucial to understand the importance of braces. These elements provide lateral stability, preventing the structure from swaying under load or adverse weather conditions. According to recent industry reports, scaffolding-related accidents account for approximately 30% of fatalities in the construction sector, emphasizing the need for proper installation and maintenance of scaffolding components.

Tips: Ensure that all components are regularly inspected for wear and tear to maintain safety standards. Use appropriate safety gear for workers on the scaffolding, as this not only ensures compliance with safety regulations but also reduces the risk of accidents. Investing in quality scaffolding components can result in long-term cost savings and enhanced safety on the job site. Properly training workers on the assembly and disassembly of the ringlock system is essential to maximize the efficiency and effectiveness of the scaffolding setup.

The connection mechanism in ringlock scaffolding is pivotal to its structural integrity and ease of assembly. This system utilizes a series of components designed to interlock securely, allowing for quick setup and dismantling while ensuring safety during construction activities. Each component, including ledgers, standards, and diagonal braces, plays a crucial role in forming a stable platform. The unique round design of the ringlock nodes allows for multiple connection points at any angle, enabling a versatile arrangement that can adapt to various project requirements.

Furthermore, the design minimizes the risk of misalignment during assembly, as each component easily fits into the corresponding node. This efficiency not only enhances safety on-site but also speeds up the workflow, allowing contractors to allocate their time and resources more effectively. The ringlock system's adaptability further extends to its compatibility with other scaffolding methods, making it a valuable choice for contractors looking for a reliable and flexible scaffolding solution. Understanding these connections helps project managers and site workers optimize their scaffolding systems, ensuring stability and safety throughout the construction process.

| Component | Description | Material | Weight (kg) |

|---|---|---|---|

| Standards | Vertical support member | Steel | 15 |

| Ledgers | Horizontal support member | Steel | 10 |

| Transoms | Cross support for planks | Steel | 8 |

| Base Plates | Distributes load from standards | Steel/Aluminum | 5 |

| Braces | Provides stability and support | Steel | 6 |

| Connecting Pins | Holds components together | Steel | 0.5 |

| Decking | Work surface for platform | Plywood/Metal | 20 |

| Guard Rails | Prevents falls from edges | Steel | 4 |

| Toe Boards | Prevents materials from falling | Wood/Steel | 3 |

| Corner Brackets | Supports corners of the scaffold | Steel | 2 |

When utilizing Ringlock scaffolding components in construction projects, safety should always be a primary concern. Proper assembly and disassembly of scaffolding systems are critical to preventing accidents. Workers must be trained to recognize the importance of weight limits and ensure that the load is evenly distributed. Overloading scaffolding can lead to structural failure, resulting in severe injuries. Regular inspections of all components, including connectors and braces, are essential to ensure they are in good condition and functioning correctly.

Another essential safety consideration is the protection of workers at height. Guardrails and toe boards must be installed according to safety regulations to prevent falls. It is equally important to ensure that the scaffolding is erected on stable ground, as shifting or unstable surfaces can compromise the integrity of the structure. Personal protective equipment, such as hard hats and harnesses, should be used by all personnel working on or near the scaffolding. By prioritizing these safety measures, construction teams can create a safer work environment and reduce the risk of accidents associated with Ringlock scaffolding components.

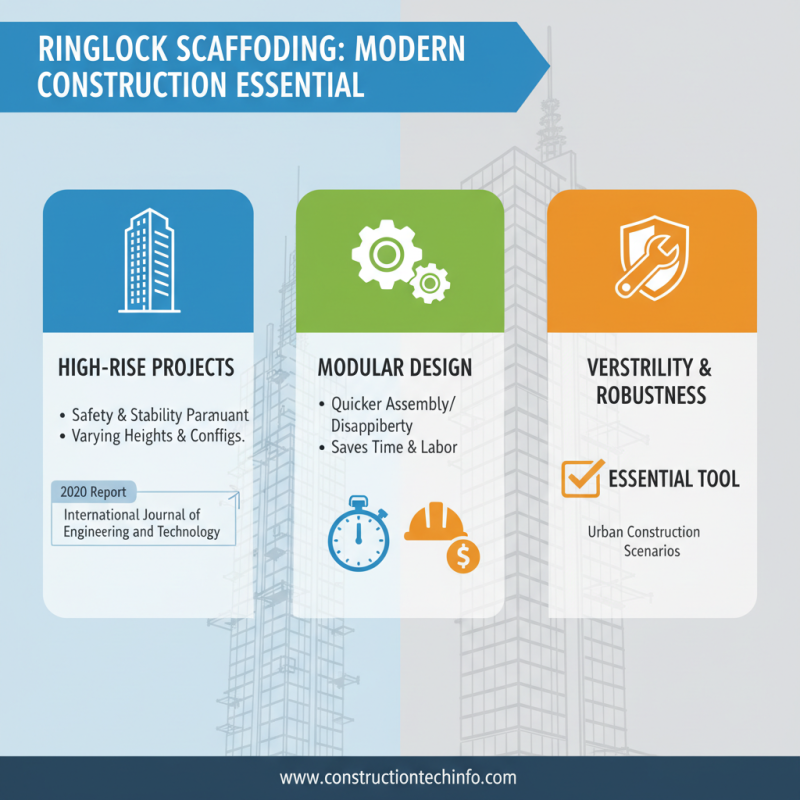

Ringlock scaffolding has become an essential tool in modern construction, thanks to its versatility and robustness. One of the primary applications of Ringlock scaffolding is in high-rise building projects, where safety and stability are paramount. According to a 2020 report by the International Journal of Engineering and Technology, the modular design of Ringlock systems allows for quicker assembly and disassembly, saving time and labor costs. This adaptability makes it ideal for projects that require varying heights and configurations, which is often the case in urban construction scenarios.

In addition to high-rise buildings, Ringlock scaffolding is widely used in bridge construction and renovations. A study published in the Journal of Construction Engineering highlighted that the efficient load distribution provided by Ringlock scaffolding leads to improved safety for workers and a reduction in on-site accidents by as much as 20%. Furthermore, the ability to create complex shapes and support multiple levels makes Ringlock scaffolding a favorite among contractors managing intricate architectural designs. This flexibility not only enhances productivity but also ensures compliance with stringent safety regulations in the construction industry.