+86 18531742341

+86 18531742341

Leave Your Message

In the ever-evolving construction industry, safety, efficiency, and adaptability have become paramount in ensuring successful project outcomes. One significant innovation that has gained traction in recent years is the Ringlock Scaffold system. This advanced scaffolding solution provides a myriad of benefits that cater to the diverse needs of modern construction practices. The Ringlock Scaffold stands out for its ease of assembly and disassembly, robust structural integrity, and compatibility with various construction environments, making it an indispensable tool for contractors and construction managers alike.

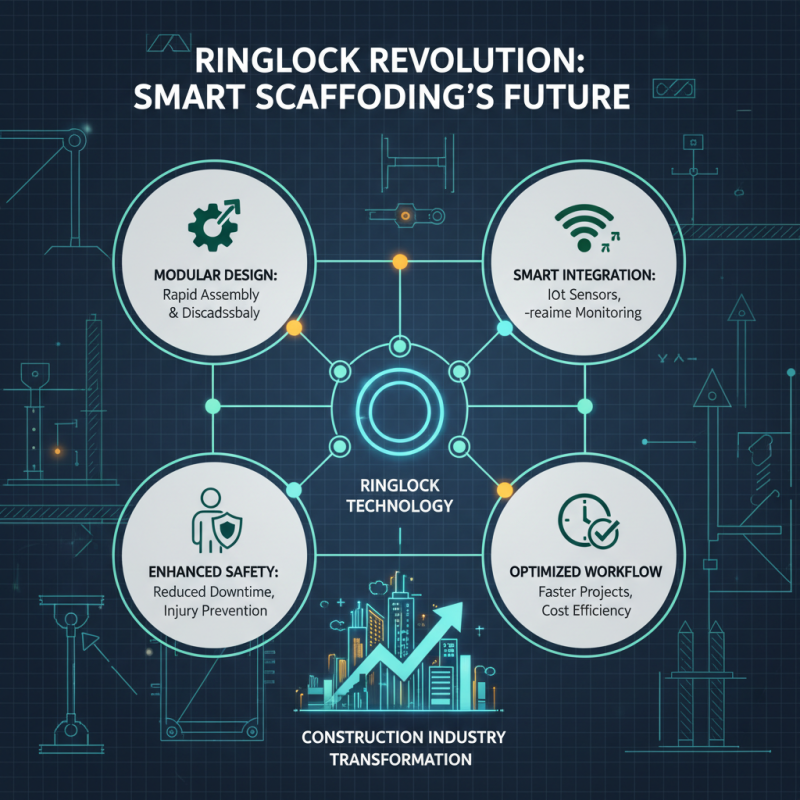

As the demand for safer and more efficient building processes continues to grow, the applications of the Ringlock Scaffold are proving to be far-reaching. Its modular design allows for versatility in configuration, accommodating different project heights and complexities while ensuring worker safety at all times. Additionally, the Ringlock Scaffold system enhances workflow efficiency, allowing for quicker project turnaround times, which is an essential factor in today’s competitive construction landscape. This article delves into the top benefits and applications of the Ringlock Scaffold, illustrating how it is revolutionizing construction practices and paving the way for future advancements in the industry.

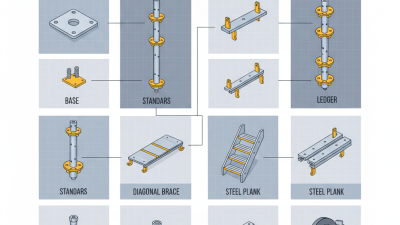

The Ringlock scaffold system has gained significant traction in the construction industry due to its flexibility and ease of use. This modular scaffolding solution consists of a series of standardized components that allow for speedy assembly and disassembly, which translates into reduced labor time and costs on job sites. With its unique lock mechanism, the Ringlock system promises enhanced stability; the horizontal and vertical components interconnect securely, providing a robust framework that can withstand heavy loads.

When considering the implementation of Ringlock scaffolding, it's essential to prioritize safety and efficiency. **Tip:** Always ensure that all components are regularly inspected for wear and tear before use to guarantee structural integrity. Additionally, employ experienced personnel for assembly to maintain high safety standards and compliance with local regulations.

Another key advantage of the Ringlock scaffold is its adaptability to various construction projects, from residential buildings to large commercial constructions. Its modular design allows for customization according to the specific requirements of each project, facilitating efficient use of space and resources. **Tip:** Plan the scaffold layout early in the project to streamline workflow and optimize access to work areas, ensuring that all team members can operate safely and effectively.

The Ringlock scaffold system is poised to become a pivotal asset in the construction industry in 2025, offering an array of key benefits that enhance safety, efficiency, and adaptability on job sites. One of the primary advantages of using Ringlock scaffold is its impressive load-bearing capacity, which allows for heavy materials and equipment to be supported with stability. This facilitates a more streamlined workflow as construction teams can work with greater confidence, knowing that their scaffolding can withstand the demands of the job.

In addition to its structural integrity, Ringlock scaffolding is characterized by its quick assembly and disassembly features. This time-saving benefit enables construction projects to maintain schedules more effectively, reducing downtime between phases. Furthermore, the modular design of the Ringlock system allows for versatile configurations, making it suitable for a diverse range of projects, from tall buildings to intricate façades. As job sites increasingly require flexible solutions, the adaptability of Ringlock scaffolds positions them as a preferred choice for contractors and construction managers in 2025.

Ringlock scaffolding is revolutionizing the construction sector by offering unparalleled versatility and safety across a variety of applications. Its unique design allows for quick assembly and disassembly, making it an ideal choice for diverse construction projects, from residential buildings to large-scale commercial complexes. The modular nature of Ringlock scaffolding enables it to be easily adapted to different structures, supporting various functions such as access platforms, shoring, and formwork, thereby increasing operational efficiency on job sites.

Moreover, Ringlock scaffolding excels in providing a stable working environment, which is essential for ensuring worker safety. Its robust interlocking system enhances load-bearing capacity, allowing it to support heavy materials and equipment. This feature is particularly beneficial in high-rise construction, where scaffolding must withstand significant weight and pressure. Additionally, its adaptability ensures that it can be utilized in challenging terrains and situations, such as sloped surfaces or tight spaces, making it a highly sought-after solution in the ever-evolving construction landscape.

The adoption of ringlock scaffolding in the construction industry is reshaping how projects are organized, especially when compared with traditional scaffolding solutions. One of the primary advantages of ringlock systems is their modular design, which allows for quick assembly and disassembly. This not only reduces labor costs but also minimizes downtime, enabling projects to progress at a faster pace. Unlike traditional scaffolding, which often requires multiple components and complex setup procedures, ringlock scaffolds can be erected efficiently with fewer parts, leading to safer working environments and enhanced productivity on site.

Another point of comparison lies in the structural integrity and versatility of ringlock scaffolding. Traditional scaffolds may struggle to provide the same level of load capacity and stability, especially on uneven terrain. The ringlock system features a robust design that can adapt to various construction needs, supporting different heights and configurations without compromising safety standards. This adaptability ensures that construction teams can tackle a wider range of projects while utilizing fewer resources, making ringlock scaffolding not only a practical choice but also a more sustainable one. As the industry evolves, the integration of innovative scaffolding solutions like ringlock systems signifies a shift towards enhanced efficiency and reliability.

The future of Ringlock scaffold technology is poised to revolutionize the construction industry through innovation and enhanced efficiency. As projects demand quicker turnaround times and greater flexibility, Ringlock scaffolding offers modular systems that can be easily assembled and disassembled. This adaptability not only improves site safety but also reduces downtime, allowing for a streamlined workflow that meets the growing demands of contemporary construction dynamics. The integration of smart technologies, such as IoT sensors, is expected to facilitate real-time monitoring of structural integrity, further ensuring worker safety and enhancing the overall efficiency of scaffolding systems.

Moreover, sustainability is becoming a key trend in the construction sector, and Ringlock scaffolds are aligning with this vision. Future developments may focus on incorporating eco-friendly materials and practices into scaffold design, minimizing environmental impact. Enhanced durability will be crucial, with advancements in material science leading to scaffolds that require less maintenance and have longer lifespans. As the construction industry continues to evolve, the use of Ringlock scaffolding is set to increase, driven by the need for more efficient, safer, and sustainable solutions in building projects worldwide.