+86 18531742341

+86 18531742341

Leave Your Message

In the construction industry, safety and efficiency are paramount. Scaffold planks play a crucial role in achieving both. According to a recent report by the Occupational Safety and Health Administration (OSHA), nearly 65% of construction accidents happen due to falls. To reduce these risks, the proper use of scaffold planks is essential. Experts emphasize the importance of quality. John Smith, a recognized expert in scaffolding, stated, “The strength and reliability of scaffold planks can determine the safety of a construction site.”

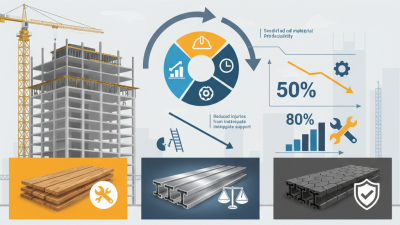

Investing in high-quality scaffold planks can enhance worker protection. A study from the National Institute for Occupational Safety and Health (NIOSH) highlights that inadequate scaffolding leads to 10% of fall-related injuries. Such statistics underscore the necessity of using appropriate materials. While many companies utilize scaffold planks, not all prioritize the correct installation and maintenance. Mistakes in these areas often result in hazardous conditions.

To navigate these challenges, workers must be adequately trained. Drawing from real experiences, many teams encounter obstacles when it comes to safe setup procedures. Addressing these issues is crucial. Construction professionals must remain vigilant about the equipment's integrity. Robust scaffold planks can significantly influence project outcomes and worker safety, allowing the industry to aim for better safety records.

Scaffold planks come in various types and materials, each with its own strengths and weaknesses. Wooden planks are commonly used. They offer flexibility and ease of use. However, they can warp or rot over time, especially when exposed to moisture. This can lead to unsafe working conditions. A report by Occupational Safety and Health Administration (OSHA) indicates that nearly 35% of construction accidents involve inadequate scaffolding.

Aluminum planks are lightweight and resistant to corrosion. These features make them popular on construction sites. However, they may lack the load capacity that wooden planks provide. In a study by the American National Standards Institute (ANSI), it was found that aluminum planks should be regularly inspected to ensure safety standards. Another option is composite planks, which combine plastic and wood fibers. They are durable and resistant to moisture but can be more expensive.

Choosing the right scaffold plank is crucial. Safety should always be the top priority. Every type has its trade-offs. It's important for contractors to evaluate their specific needs. Regular maintenance and inspection are key, regardless of the material chosen. Unaddressed deficiencies can lead to accidents on site. The industry trend shows that investing in quality materials can reduce incidents significantly.

When using scaffold planks, safety regulations are paramount. These planks must be inspected regularly. Look for signs of damage or wear. Cracks or warping can weaken the structure. Each plank should meet safety standards for weight and load. This ensures they can support workers and materials effectively.

Personal protective equipment is also essential. Hard hats, safety glasses, and harnesses should be worn. Training is critical. Workers must understand how to set up and use scaffolding safely. Regular safety meetings can reinforce these procedures.

Additionally, ensuring the ground is level can prevent accidents caused by shifting or tipping. Manual handling of planks requires attention. Lifting heavy planks alone can lead to injuries. Always use lifting techniques or ask for help.

Even with regulations in place, there are times when human error occurs. Learning from these mistakes can improve future safety practices. Staying vigilant and proactive about safety fosters a secure construction environment.

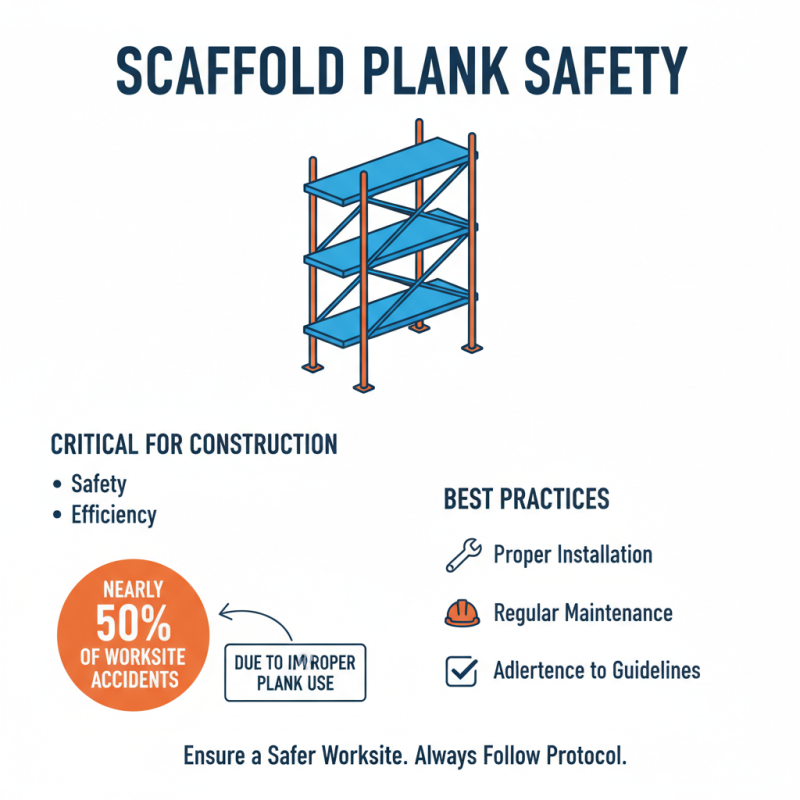

Scaffold planks are critical in construction. Proper installation and maintenance practices ensure safety and efficiency. Research indicates that improper plank use can lead to nearly 50% of worksite accidents. This statistic highlights the need for careful adherence to best practices.

When installing scaffold planks, checking for damage is crucial. Planks should be inspected for cracks, rot, or any signs of wear. Routine inspections can significantly reduce risks. According to the Occupational Safety and Health Administration (OSHA), nearly 70% of scaffold-related accidents stem from plank failures. The regulations recommend using planks rated for the load they will bear.

Maintenance plays a significant role as well. Regular cleaning can prevent slips and falls. Ensure that planks are placed correctly, resting on stable supports. Any disturbances during construction can compromise their integrity. While workers often rush, taking the time to ensure safety is essential. Reflecting on past incidents can lead to safer work environments. Ultimately, prioritizing proper installation and maintenance of scaffold planks significantly impacts overall safety in construction.

Effective use of scaffold planks can significantly enhance safety and efficiency on construction sites. Reports indicate that about 65% of accidents in construction involve improper use of scaffolding. Therefore, it’s crucial to implement techniques that maximize safety while maintaining productivity.

One practical technique is to ensure proper spacing and alignment of planks. Misalignment can lead to safety hazards and decreased workflow. Studies show that properly aligned scaffold planks can reduce the risk of slips and falls by up to 30%. Regular inspections should be conducted to check for wear and tear, as damaged planks can compromise both safety and efficiency.

Additionally, planning is key. Workers should always be assigned roles that fit their skills. Proper training is equally important; training programs can reduce accidents by 40%. It’s not enough to just place scaffold planks—they must be arranged thoughtfully and utilized efficiently. Ideal configurations increase worker accessibility to tools and materials, which contributes to smoother operations. Continuous reflection on these practices can lead to improved methodologies in scaffold use.

When using scaffold planks, risk management is crucial. Workers must identify potential hazards on the site. Strong winds can compromise stability. Loose materials can create tripping hazards. Taking these risks seriously is vital for safety.

Emergency procedures should be established before construction begins. Ensure everyone knows whom to contact in case of an accident. Regular drills can prepare workers for unexpected situations. Having first aid kits on-site is a must. It’s easy to overlook these details, but preparedness saves lives.

Training is essential. Everyone using scaffold planks should understand their limits. It’s important to regularly inspect equipment. Damaged planks should be removed immediately. Rushing inspections can lead to overlooking critical issues. Encourage communication among workers. They should feel comfortable reporting unsafe conditions.