+86 18531742341

+86 18531742341

Leave Your Message

In the construction industry, safety is paramount. Scaffold clamps play a critical role in ensuring that scaffolding remains stable and secure. According to a report from the Occupational Safety and Health Administration (OSHA), falls are a leading cause of fatalities in construction, accounting for 33% of all deaths. Properly installed scaffold clamps can significantly reduce these risks.

Scaffold clamps firmly hold scaffold components together. This enhances structural integrity and improves worker safety. A study from the National Institute for Occupational Safety and Health (NIOSH) emphasizes that sturdy clamps reduce the chances of accidents and injuries. Without them, scaffolding can wobble or collapse, endangering lives.

Though many acknowledge their importance, some still neglect regular inspections and proper installation practices. A survey revealed that 40% of construction sites did not follow best practices regarding scaffold setup. This gap in safety highlights a need for better training and adherence to guidelines among workers. Implementing proper use of scaffold clamps is a step towards fostering a safer construction environment.

Scaffold clamps are a vital component of any construction site. They ensure that scaffolding systems remain stable and secure. According to industry reports, improper scaffold use contributes to nearly 50% of fall-related injuries in construction. Without reliable clamps, the risk of accidents rises significantly. Workers depend on these fixtures for safety during elevated tasks.

The importance of scaffold clamps cannot be overstated. They connect the scaffold poles and provide support. A study from a construction safety organization shows that the use of high-quality clamps can reduce accidents by over 30%. However, many projects still use outdated or damaged clamps. This oversight can lead to catastrophic consequences.

It's essential to regularly inspect these devices. Wear and tear can compromise their reliability. Some workers may underestimate the risks involved. Clamps that look fine on the surface may have hidden defects. Education and training about scaffold safety, including the significance of clamps, are often overlooked in the field. Structures erected without proper attention to clamp standards frequently face instability, resulting in a hazardous work environment.

Scaffold clamps are crucial for safety in construction. They provide stability and strength to scaffold structures. Understanding the various types of scaffold clamps can enhance safety and efficiency on job sites.

One common type is the right-angle clamp. This clamp holds two scaffold tubes at a 90-degree angle. It is essential for creating secure corners. Another type is the swivel clamp. This allows for versatile positioning of tubes. Swivel clamps enable adjustments for uneven surfaces, ensuring safety during construction.

**Tip:** Always inspect clamps before use. Damaged clamps can compromise safety. Replace any worn-out components immediately.

Additionally, a third type, the quick-release clamp, speeds up assembly and disassembly. This type is particularly useful in scenarios requiring frequent adjustments. However, it’s essential to ensure that the quick-release mechanism is secure. A loose clamp can lead to accidents.

**Tip:** Train workers on proper clamp usage. Regular training reduces the risk of mistakes. It is important to prioritize safety above all.

Scaffold clamps play a pivotal role in construction safety. Proper installation is paramount. Key safety standards dictate how these clamps should be used. Workers must understand the weight limits for scaffolding. Each clamp must securely attach all components. When installed incorrectly, it can lead to catastrophic failures.

Many workers overlook the importance of checking clamps regularly. Inspections should happen daily, especially in adverse weather. Corrosion or damage can compromise safety. If a clamp is rusty, it requires immediate replacement. Remember, small oversights can escalate quickly.

Training on proper installation techniques is essential. Every worker should know the safety guidelines. Poorly installed clamps can put lives at risk. A simple misalignment might seem minor but can result in severe consequences. Understanding the standards helps in creating a safer work environment.

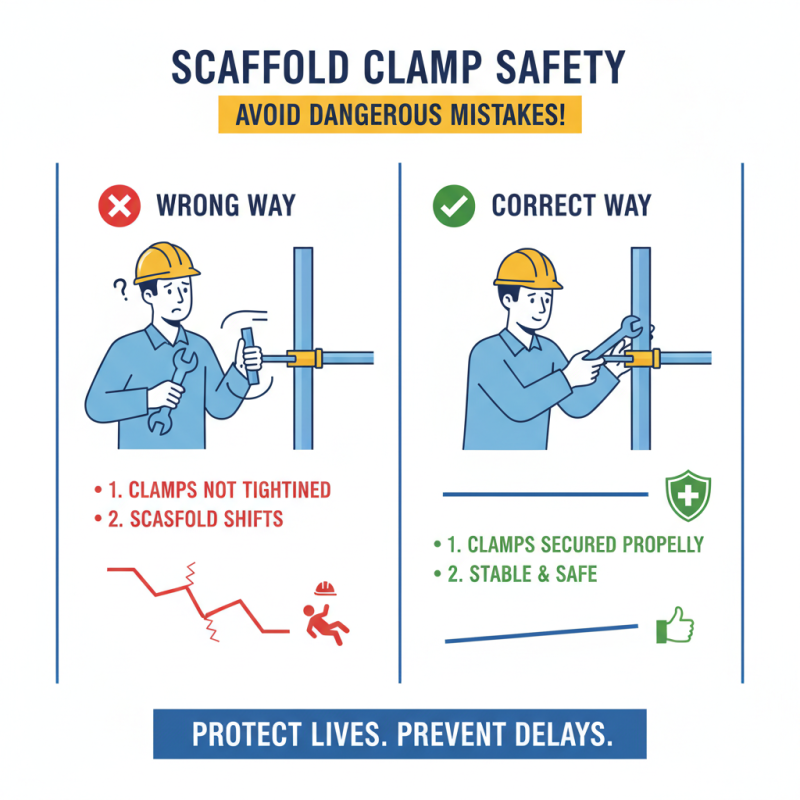

Using scaffold clamps correctly is vital for construction safety. However, many workers make common mistakes that can lead to serious accidents. One frequent error is improperly securing the clamps. When clamps are not tightened adequately, scaffolding may shift. This instability can endanger lives and cause costly delays.

Another mistake involves overlooking the manufacturer's guidelines. Every clamp is designed with specific weight limits and usage rules. Skipping these instructions may lead to incorrect applications. Additionally, many overlook routine inspections. Not checking for wear and tear or corrosion can result in failures during critical moments. With heavy materials at heights, this oversight can have catastrophic consequences.

Workers often rush in their tasks, leading to compromised safety. Taking the time to ensure proper clamp usage will protect everyone on-site. Ultimately, fostering a culture of safety should be a priority. Small mistakes can spiral into large problems. Reflection on past errors can guide better practices moving forward.

Scaffold clamps play a crucial role in construction safety. These small but powerful components secure scaffolding frames together. They prevent the collapse of structures, which is vital in protecting workers. When workers feel secure, they can focus better on their tasks. This focus boosts overall efficiency on the job site. However, improper installation of these clamps can lead to accidents.

The impact of scaffold clamps goes beyond mere safety. Workers are more efficient when they trust their equipment. A well-secured scaffold allows for safe movement and access to high areas. This reduces the need for constant adjustments and repairs. Yet, some workers may overlook regular inspections. Neglecting this step can lead to serious safety hazards. The process of checking clamps should be routine but is often skipped.

While scaffold clamps enhance safety, they also require proper training. Workers must understand how to use them correctly. Misuse can negate the benefits they offer. Regular training sessions can address this gap. Encouraging a safety-first culture is essential. The construction site should be a space where every worker feels both safe and productive.

| Aspect | Description | Impact on Safety | Impact on Efficiency |

|---|---|---|---|

| Installation | Scaffold clamps secure framework and are easy to install. | Reduces risk of accidents due to unstable scaffolding. | Speeds up the process of erecting scaffolding. |

| Durability | Made from sturdy materials to withstand heavy loads. | Ensures that the scaffold remains safe under stress. | Reduces need for frequent replacements and maintenance. |

| Versatility | Can be used with various types of scaffolding. | Enhances safety across different applications. | Allows for flexible configurations to suit projects. |

| Ease of Use | Simple mechanisms allow for quick adjustments. | Decreases chances of improper setup by workers. | Improves workflow by minimizing setup time. |

| Compliance | Meets industry safety standards and regulations. | Ensures the project adheres to safety laws. | Reduces potential legal issues that could cause delays. |