+86 18531742341

+86 18531742341

Leave Your Message

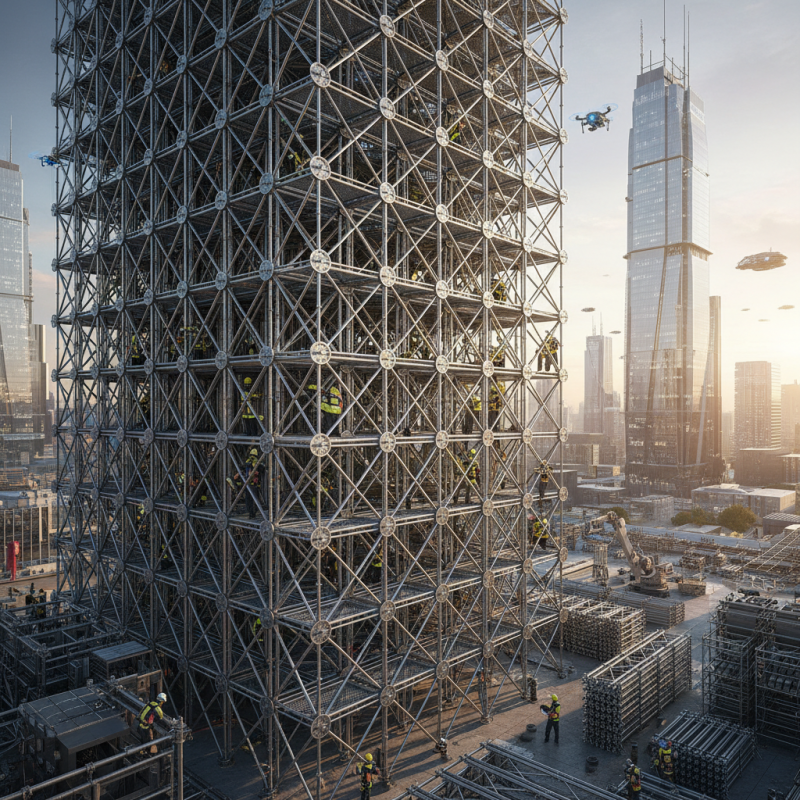

The Ringlock Scaffolding System has gained significant attention in the construction industry. Its innovative design ensures safety and efficiency on job sites around the world. In 2026, this system is poised to offer even more benefits, adapting to the ever-evolving needs of builders.

This scaffolding system is recognized for its quick assembly and flexibility. Workers can set it up easily, saving valuable time. The robust structure provides stability, crucial for high-rise projects. However, it's essential to monitor the condition of the scaffolding regularly. Neglect can lead to safety hazards. The maintenance of the Ringlock system remains a topic for reflection.

In addition to safety, the system is known for its cost-effectiveness. It reduces the need for extra components, streamlining logistics. Some still question whether it meets all project requirements effectively. Future developments may address these concerns, enhancing reliability and user satisfaction. Overall, the Ringlock Scaffolding System is an exciting advancement in construction technology.

The Ringlock Scaffolding System is a modern scaffolding solution popular in the construction industry. It features a unique design that allows for quick assembly and disassembly. Each element locks securely into place, providing stability and safety. The system’s versatility makes it suitable for various projects, from small renovations to large-scale construction.

One of the key benefits is its lightweight quality. Workers can maneuver it easily, which increases efficiency on-site. However, it's essential to ensure all parts are correctly assembled. Misalignment can lead to safety risks. Additionally, while the system is designed for easy use, proper training is vital. Workers need to understand how to operate it safely to avoid potential accidents.

Different environments may present challenges. For instance, uneven ground can affect stability, requiring additional adjustments. Operators should regularly inspect components for wear and damage. Ignoring maintenance could compromise the whole system. Despite its advantages, the Ringlock Scaffolding System demands a mindful approach to usage and upkeep.

The Ringlock Scaffolding System is gaining traction for its modular design and versatility. Key components are essential for understanding its structure. The main parts include vertical standards, horizontal ledgers, and diagonal braces. Vertical standards form the backbone of the system. They are typically positioned at regular intervals to ensure stability.

Horizontal ledgers connect the vertical standards, creating a robust framework. Their secure attachment allows for multiple levels of scaffolding. Diagonal braces act as reinforcing elements, adding extra support. These components work together to create a safe working environment.

One flaw is that incorrect assembly can lead to safety hazards. Workers must ensure every connection is tight. Regular inspections are critical, but can often be overlooked. This oversight can result in unstable structures. Each component plays a role, and understanding their interaction is crucial for effective use.

Ringlock scaffolding is gaining attention for its numerous benefits in construction. This system is versatile and easy to assemble. It consists of vertical standards and horizontal ledgers. Workers can build stable platforms quickly. The design allows for adjustments in height and configuration. This flexibility is vital for various types of projects. Whether it's a small renovation or a large building, it adapts well.

One significant advantage is the safety it provides. The ringlock system creates a secure structure, minimizing the risk of accidents. Workers can feel confident while navigating heights. Load distribution is efficient, reducing the chances of collapse. However, it still requires diligent training for proper use. Inexperienced teams may still face challenges, like misalignment. Regular inspections are necessary to maintain safety.

Moreover, the ringlock system is cost-effective. It saves time during setup and takedown. Projects can progress faster, leading to potential savings. Yet, some teams might overlook the upfront investment. Initial costs can seem high, but they pay off in the long run. Balancing cost and efficiency is important for every construction manager. This system is changing how we think about scaffolding, showing promise for the future.

The Ringlock Scaffolding System has gained attention for its robust safety features. This scaffolding system's design allows for quick assembly and disassembly without sacrificing stability. According to a 2023 report by the International Scaffolding Association, using Ringlock systems can reduce labor costs by up to 30%. This is noteworthy, considering safety and efficiency are paramount on construction sites.

Safety features include a unique locking mechanism that prevents accidental dislodgment. This system significantly lowers the risk of falls, a common hazard in construction. Reports indicate that fall-related incidents have dropped by 25% in projects utilizing Ringlock scaffolding. Even under heavy loads, the Ringlock system maintains structural integrity, ensuring worker safety.

Tip: Always inspect the locking mechanisms before use. Ensure all components are free from damage. Regular maintenance enhances the system's longevity and ensures safety compliance. Remember, the best safety measures are proactive. While Ringlock is reliable, it is essential to reflect on potential site-specific hazards that might still pose risks.

The Ringlock scaffolding system is gaining traction in construction. By 2026, innovations in this system promise notable enhancements. Industry reports project a growth rate of 7% annually in scaffolding solutions. The ease of assembly and the robust nature of Ringlock are key to this increase.

Future trends indicate a shift toward modular designs. These designs allow for quicker adaptation on-site. Reports suggest that modular systems can reduce assembly time by up to 30%. Improved materials, such as high-strength steel, are becoming more prevalent. They provide better safety and durability. However, not all projects see immediate benefits. Transitioning to new materials often requires training.

Digital integration is another area of growth. Smart technology can enhance safety inspections. Data analytics will aid in optimizing scaffold setups. However, the industry faces obstacles. Not every construction crew is tech-savvy. Theoretical benefits do not always translate into practice. Companies must be cautious. Balancing innovation with operational realities is crucial as we move towards 2026.

| Dimension | Description | Benefits |

|---|---|---|

| Structure Type | Modular and versatile design | Easier assembly and disassembly |

| Material | High-strength steel | Enhanced durability and strength |

| Load Capacity | Up to 450 kg/m² | Supports heavy loads for various projects |

| Height Reach | Up to 30 meters | Suitable for high-rise construction |

| Safety Features | Integrated safety guardrails | Improved safety for workers |

| Innovative Components | Quick-lock connections | Faster setup times |