+86 18531742341

+86 18531742341

Leave Your Message

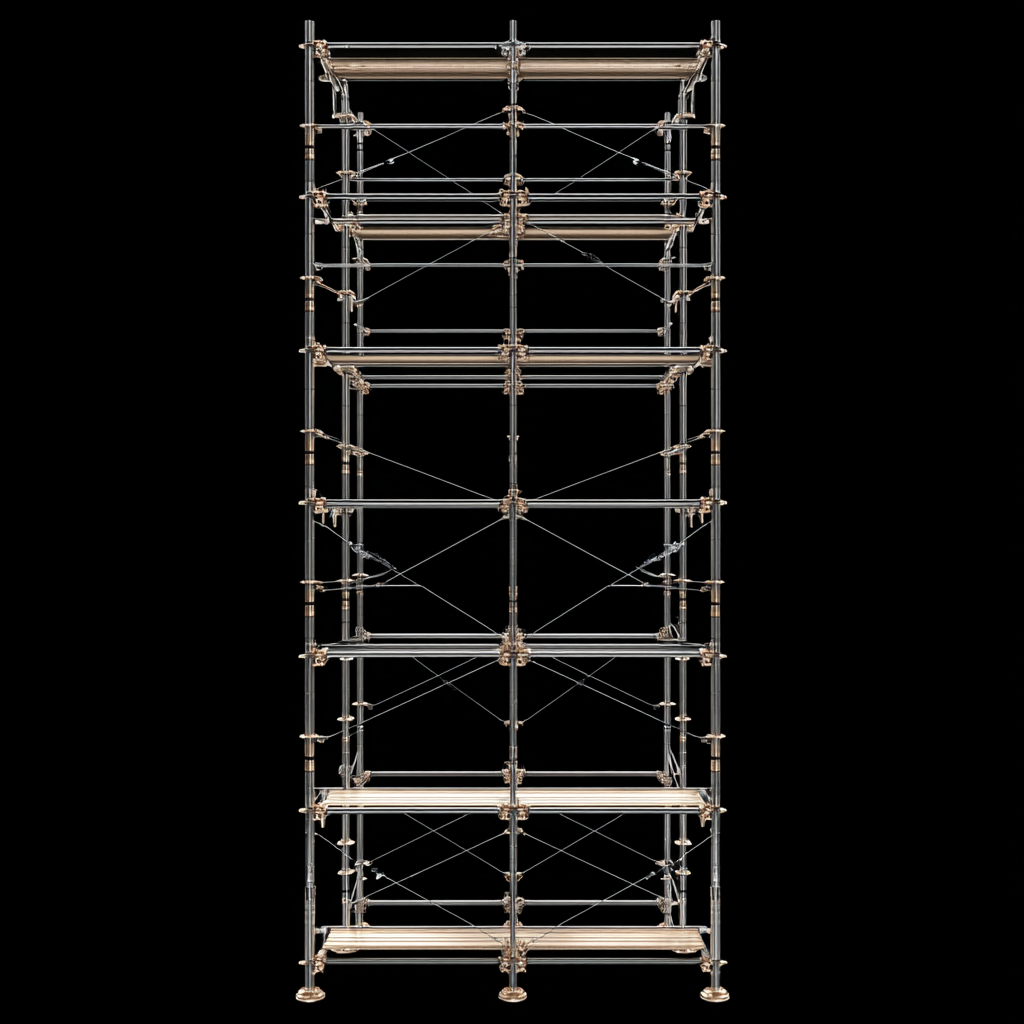

In the rapidly evolving construction industry, Scaffold Ringlock systems have emerged as a cornerstone of safety and efficiency on job sites worldwide. According to a recent industry report by Grand View Research, the global scaffolding market size is expected to reach USD 5.53 billion by 2025, with a significant portion attributed to innovative systems like Scaffold Ringlock which provide remarkable versatility and strength. As construction activities rebound post-pandemic, the demand for reliable and high-quality scaffolding solutions is surging. In this landscape, Chinese manufacturers are pioneering excellence in Scaffold Ringlock production, being recognized globally for their adherence to stringent quality standards. This blog explores how the commitment to innovation and quality in Chinese manufacturing is leading the way in providing trusted, consistent products that meet international safety requirements.

The scaffold ringlock system is increasingly gaining traction in the construction industry due to its enhanced safety features and ease of use. According to a report by Research And Markets, the global scaffolding market is expected to grow by 6.3% annually, with ringlock scaffolding emerging as a preferred choice for major projects. This innovative approach allows for rapid assembly and disassembly, making it particularly valuable in urban settings where time and space are at a premium.

Advancements in manufacturing techniques have significantly improved the quality and durability of scaffold ringlock systems. In 2023, manufacturers are leveraging technologies such as automated welding and high-strength steel to create products that exceed international safety standards. A recent analysis by MarketsandMarkets indicates that the demand for lightweight yet robust scaffolding solutions has surged, with ringlock systems witnessing a 40% increase in adoption over the last five years. The evolution of these techniques not only enhances performance but also aligns with global sustainability goals, as manufacturers focus on reducing waste and increasing the recyclability of materials.

The global demand for scaffold ringlock systems has been witnessing a remarkable upsurge, driven by several key market trends. According to a recent report by Grand View Research, the global scaffolding market size is projected to reach USD 20 billion by 2025, with a compound annual growth rate (CAGR) of approximately 5.5% during the forecast period. This growth is primarily fueled by booming construction activities and an increasing focus on safety standards across various sectors, including commercial, residential, and infrastructure projects.

Moreover, the rise in investments in infrastructure development in emerging economies is significantly contributing to the demand for scaffolding systems. The Asian Development Bank (ADB) estimates that Asia alone will require USD 26 trillion in infrastructure investment from 2016 to 2030. As scaffold ringlock systems offer unmatched flexibility and durability, they are increasingly favored by construction companies looking for efficient and reliable solutions. Additionally, the shift towards modular construction techniques is further propelling the use of ringlock systems, as these can be quickly assembled and disassembled, reducing labor costs and project timelines.

Ensuring safety in scaffold ringlock manufacturing is paramount, especially as it serves as a vital component in construction projects worldwide. The stringent adherence to safety standards and compliance regulations is not just a legal obligation but a commitment to protecting workers on-site. In China, manufacturers are increasingly investing in advanced technologies and training programs to meet international safety protocols. This dedication to excellence not only enhances product reliability but also builds trust with clients globally.

Quality control is a cornerstone of the scaffold ringlock production process. Manufacturers conduct rigorous tests on materials and finished products to certify that they meet or exceed safety standards. Each batch undergoes comprehensive inspections and validations to prevent any defects that could compromise structural integrity. By prioritizing safety and quality, Chinese manufacturers are setting new benchmarks in the industry, positioning themselves as leaders in the global market for scaffold ringlock systems.

In the construction industry, the efficiency and safety of scaffolding systems are of paramount importance. One innovative solution that has gained popularity is the Scaffold Ringlock system, known for its modular design and ease of assembly. When evaluating the cost-effectiveness of Scaffold Ringlock solutions, it becomes evident that this system not only reduces labor costs but also minimizes material waste, contributing to overall project savings. The ease of installation ensures that workers can set up scaffolding quickly, allowing projects to stay on schedule while avoiding the expenses associated with delays.

Furthermore, a comparative analysis of Scaffold Ringlock systems with traditional scaffolding methods reveals significant advantages. The Ringlock's versatility and robustness allow it to adapt to various site conditions, enhancing its lifespan and reducing the need for frequent repairs or replacements. Companies that choose Scaffold Ringlock solutions often report lower long-term expenses due to its durability and efficiency. As the global demand for safe and cost-effective construction solutions rises, the Scaffold Ringlock system is positioning itself as a frontrunner in meeting these requirements, paving the way for construction excellence worldwide.

The scaffold ringlock manufacturing sector is poised for significant transformation, driven by innovations and sustainability efforts. As highlighted in recent reports, the global construction scaffolding market is projected to exceed $62.95 billion by 2029, reflecting an acceleration in infrastructure development worldwide. This surge presents a unique opportunity for manufacturers to innovate their processes and materials, enhancing not only efficiency but also safety and environmental impact.

Sustainable practices in scaffold ringlock production are becoming imperative. Manufacturers are increasingly focusing on utilizing eco-friendly materials and energy-efficient production methods. Such innovations not only comply with stricter regulations but also appeal to an increasingly environmentally conscious market. As demand for sustainable construction solutions grows, companies embracing these principles will likely gain a competitive edge, positioning themselves as leaders in the global market. The future of scaffold ringlock manufacturing is not just about meeting the current demands but anticipating the needs of a sustainable world, ensuring a robust response to both industry growth and environmental challenges.