+86 18531742341

+86 18531742341

Leave Your Message

In the construction industry, safety and efficiency go hand in hand, especially when it comes to scaffolding systems. The Ringlock Scaffolding System has emerged as a pivotal solution, facilitating safe work environments while enhancing productivity on site. According to John Smith, an industry expert with over 20 years of experience in scaffolding solutions, "The Ringlock Scaffolding System revolutionizes how we approach construction safety by offering a robust and adaptable framework that meets the diverse needs of our projects."

As construction sites become more complex, the demand for reliable and safe scaffolding solutions like the Ringlock Scaffolding System has increased significantly. This versatile system not only ensures worker safety but also allows for quick assembly and disassembly, making it an invaluable asset in today’s construction landscape. By understanding the best practices associated with the Ringlock Scaffolding System, professionals can maximize efficiency while minimizing risks.

In this ultimate guide, we will delve into essential tips and strategies for the effective use of the Ringlock Scaffolding System, ensuring that your projects are executed smoothly and safely. With this knowledge, we aim to empower construction teams to harness the full potential of this innovative scaffolding method, fostering a culture of safety and efficiency within the industry.

The Ringlock scaffolding system stands out due to its innovative design and robust features that cater to various construction needs. Key components of this system include vertical standards, horizontal ledgers, and diagonal braces, which work seamlessly together to provide a secure and stable platform. The vertical standards are designed to be robust, allowing them to support heavy loads while also being easily adjustable to accommodate different heights. Horizontal ledgers connect the vertical standards, creating a rigid framework to enhance overall stability, while diagonal braces offer additional structural support, preventing any lateral movement.

One of the hallmark features of Ringlock scaffolding is its modular nature, which promotes efficiency in setup and dismantling processes. The components are engineered for quick assembly without the need for special tools, making it an excellent choice for projects that require rapid deployment. Additionally, the system's versatility allows for various configurations, making it suitable for both simple and complex scaffolding requirements. Its compatibility with other scaffold systems further enhances its utility on job sites, ensuring that crews can adapt to diverse construction challenges with ease and safety.

When utilizing a Ringlock scaffolding system, adherence to safety standards and regulations is paramount to ensure the safety of all personnel on site. OSHA (Occupational Safety and Health Administration) guidelines provide a framework for safe scaffolding practices, emphasizing the importance of proper installation, maintenance, and regular inspections. All components should be certified and assembled by trained professionals who thoroughly understand the system's specifications and weight limits. Additionally, maintaining an organized worksite and ensuring that the scaffolding is securely anchored can significantly reduce the risk of accidents.

To enhance safety during scaffolding use, consider implementing these tips: First, always inspect the scaffolding before use. Look for signs of wear, damage, or misalignment that could compromise structural integrity. Second, ensure that all workers are equipped with appropriate personal protective equipment (PPE), including hard hats, harnesses, and non-slip footwear. Third, train all personnel on the correct procedures for climbing, working from height, and using safety gear effectively. By fostering a culture of safety and compliance with established regulations, the likelihood of incidents can be minimized, leading to a safer working environment.

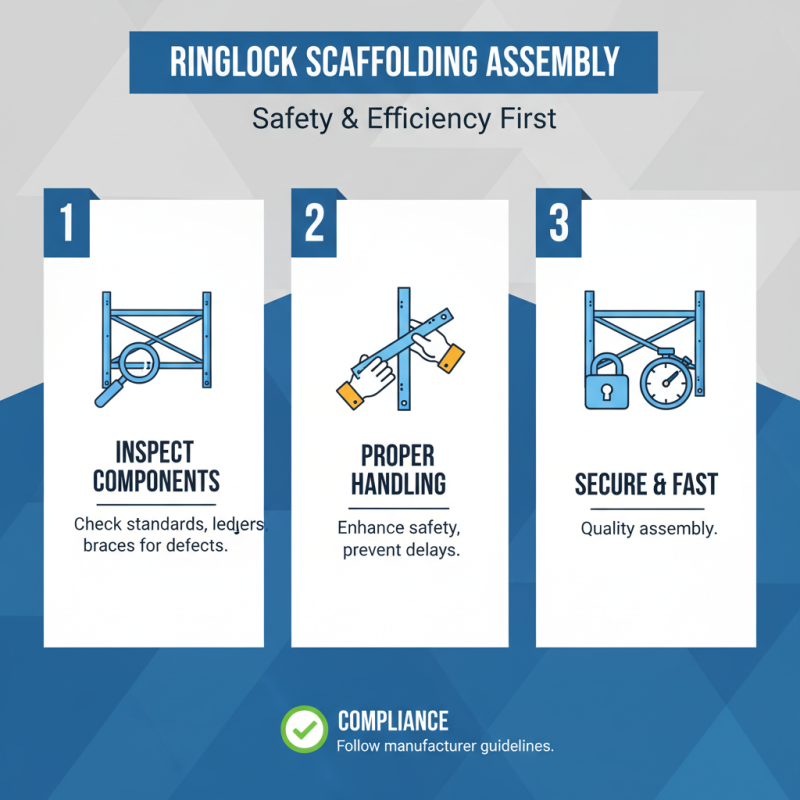

When assembling Ringlock scaffolding systems, safety and efficiency are paramount. First and foremost, ensure that all components are in good condition and free from defects before starting the assembly process. It's essential to conduct a thorough inspection of the scaffolding parts, including standards, ledgers, and braces. Proper handling of these components will not only enhance safety but also prevent unnecessary delays during assembly.

Next, follow a systematic approach to erect the scaffolding. Start by placing the base jacks on a stable and level surface to support the structure. As you assemble the vertical standards, ensure they are securely locked in place using the Ringlock system’s unique connection points. This step is crucial, as the integrity of the entire scaffolding system relies on the correct installation of these standards. Additionally, make sure to follow the recommended height-to-base ratio for stability, and always use diagonal braces to enhance the rigidity of the structure.

Finally, communicate effectively with your team during the assembly process. Designate roles and responsibilities to streamline the workflow, ensuring that each person knows their tasks clearly. Regularly check the assembly to confirm that all components are connected properly, and maintain a clean and organized workspace to avoid accidents. By adhering to these best practices, you can ensure a safe and efficient assembly of Ringlock scaffolding systems, reducing risks and enhancing productivity on site.

To ensure the longevity and reliability of a Ringlock scaffolding system, regular maintenance is essential. First, routine inspections should be conducted to check for any signs of wear or damage. This includes examining all components, such as the standards, ledgers, and braces, for rust, cracks, or deformations. Promptly addressing any identified issues can prevent costly repairs or potential failures during use. It's also important to keep components clean and free from debris, as build-up can lead to corrosion and hinder the system’s integrity.

In addition to inspections, storing the scaffolding properly when not in use is crucial. Components should be kept in a dry, well-ventilated area to avoid moisture accumulation, which can cause rust and degradation of materials. Avoid stacking heavy items on the scaffolding parts that could lead to bending or twisting. Finally, periodic lubrication of moving parts will facilitate easier assembly and disassembly, enhancing the efficiency of the system and contributing to overall safety on the job site. Adhering to these maintenance tips will help maximize the life of your Ringlock scaffolding, ensuring it remains a reliable solution for various construction tasks.

When working with the Ringlock scaffolding system, avoiding common mistakes is crucial for ensuring safety and efficiency on-site. One of the most prevalent errors is inadequate training for personnel using the system. According to industry reports, up to 70% of scaffolding accidents occur due to improper use or misunderstanding of the equipment. Comprehensive training sessions that cover assembly, load limits, and safety protocols can significantly reduce these risks.

Another common mistake is neglecting to conduct regular inspections of the scaffolding setup. It's essential to check for any signs of wear, damage, or instability before each use. Research from the Scaffold Industry Association indicates that well-maintained scaffolding can reduce accident rates by nearly 47%. Establish a daily checklist that includes visual inspections and make necessary adjustments to ensure a secure working environment.

Tip: Always ensure that all components of the Ringlock system are compatible and properly secured. Failure to align parts correctly can lead to structural failures. Additionally, use protective measures like guardrails on all open sides to prevent falls. Keeping these safety precautions in mind while using the Ringlock scaffolding system can enhance efficiency and safeguard workers on-site.

| Tip | Common Mistake | Recommended Action | Frequency of Occurrence |

|---|---|---|---|

| Ensure proper assembly of components | Skipping parts during assembly | Follow manufacturer's assembly instructions | High |

| Regularly inspect scaffolding | Neglecting to inspect for damages | Implement a routine inspection schedule | Medium |

| Use personal protective equipment (PPE) | Forgetting to wear safety gear | Conduct safety briefings before work | High |

| Follow weight load capacities | Overloading the scaffold | Signage to indicate weight limits | Medium |

| Secure the base of scaffolding | Setting up on uneven ground | Level the ground or use base plates | Low |