+86 18531742341

+86 18531742341

Leave Your Message

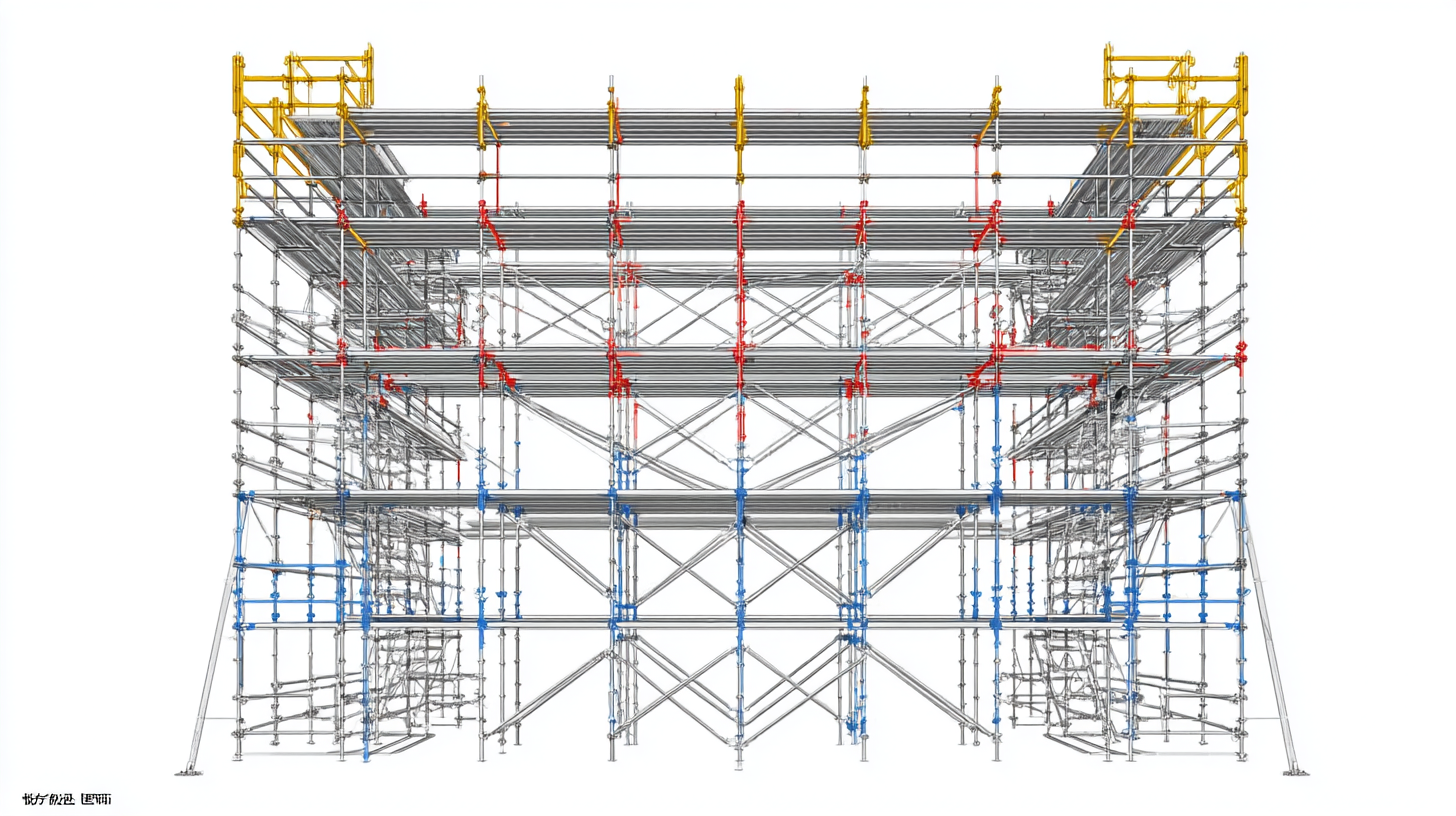

In the ever-evolving construction industry, the importance of safety and efficiency cannot be overstated, particularly when it comes to scaffolding systems. The Ringlock Scaffolding Ledger has emerged as a leading solution due to its superior design and structural integrity. According to a recent industry report by Research and Markets, the global scaffolding market is projected to reach USD 4.7 billion by 2025, with a significant portion attributed to modular systems like Ringlock scaffolding, which offer enhanced load-bearing capacity and quick assembly.

This paradigm shift towards prefabricated scaffolding not only improves safety standards on construction sites but also reduces labor costs and timelines. As we delve into the global standards for the best Ringlock Scaffolding Ledger, it's essential to emphasize the role of high-quality manufacturing—particularly from China, where innovation meets quality to fulfill the needs of global partners.

The evolution of ringlock scaffolding standards has been a significant development in the construction industry, primarily driven by the need for improved safety, efficiency, and universality across global markets. Historically, the adoption of scaffolding systems has varied greatly by region, but the push for standardized regulations became more pronounced in the early 2000s. According to a report by the International Organization for Standardization (ISO), over 70% of global scaffolding accidents can be attributed to inadequate standards and training. This has prompted the establishment of stricter guidelines for ringlock scaffolding, particularly in Europe, where the EN 12811 standard plays a critical role.

As these standards evolve, they not only enhance safety protocols but also streamline the construction process. A recent market analysis indicated that countries adhering to standardized ringlock systems have reported up to a 30% reduction in assembly time. This efficiency allows for quicker project completions without compromising safety or structural integrity. Furthermore, the harmonization of standards facilitates international trade and the adoption of best practices, ensuring that scaffolding solutions meet the diverse needs of the global construction industry while promoting worker safety across all regions.

| Region | Standard Name | Load Capacity (kN) | Material | Height (m) |

|---|---|---|---|---|

| North America | ANSI A10.8 | 45 | Steel | 3.0 |

| Europe | EN 12811 | 50 | Aluminum | 4.0 |

| Asia | GB 50907 | 40 | Steel | 3.5 |

| Australia | AS/NZS 1576 | 55 | Steel | 4.5 |

When it comes to scaffolding, particularly ringlock scaffolding, quality construction is paramount. High-quality Chinese-made ringlock scaffolding offers robust solutions built to meet international standards. According to a report by Market Research Future, the global scaffolding market is expected to reach USD 66.37 billion by 2024, with ringlock systems becoming increasingly favored due to their flexibility and ease of assembly. These features enable quicker project completions and enhanced safety, crucial factors in modern construction.

Key attributes of top-tier ringlock scaffolding include high-strength steel materials, precision manufacturing, and superior load-bearing capacities. For instance, a comprehensive industry analysis revealed that well-engineered ringlock systems can bear loads of up to 10 tons per individual ledger, which is significantly higher than traditional scaffolding options. Additionally, corrosion-resistant coatings on Chinese units ensure longevity and durability, making them suitable for diverse environmental conditions. These features combined position Chinese-made ringlock scaffolding as a leading choice in the global market, catering to both safety and efficiency in construction dynamics.

When it comes to scaffolding, the ledger is a crucial component that plays a significant role in ensuring safety and structural integrity. Understanding the global standards for ringlock scaffolding is essential for manufacturers and users alike. However, a comparative analysis between these international standards and local manufacturing practices reveals varied approaches to compliance, quality, and safety.

Globally, standards such as those set by the International Organization for Standardization (ISO) emphasize uniformity in the materials used, design specifications, and testing procedures for scaffold components. These regulations aim to ensure that all scaffolding systems, including ledgers, meet rigorous safety benchmarks. On the other hand, local manufacturing practices may prioritize cost-effectiveness and accessibility over strict adherence to these standards. This often leads to variations in quality and safety, as manufacturers might use alternative materials or omit certain testing processes to save time and reduce expenses.

The disparity between global standards and local practices raises concerns about safety in construction environments, particularly in regions where regulations are less enforced. While local manufacturers may have intimate knowledge of their specific market needs, it is crucial to align their processes with global safety standards. Bridging this gap can help enhance the overall safety of scaffolding systems, ensuring that both construction workers and the general public are protected from potential hazards associated with inferior products.

In recent years, the global scaffolding market has experienced substantial growth, driven by increasing construction activities and infrastructure developments. According to a report from Research and Markets, the global scaffolding market size is expected to reach USD 70 billion by 2027, growing at a compound annual growth rate (CAGR) of over 5% from 2020. This growth underscores the necessity for high-quality scaffolding solutions, such as ringlock scaffolding, which offer enhanced safety and efficiency compared to traditional systems.

Quality upgrades in ringlock scaffolding, particularly concerning the ledger components, directly impact a company's competitive edge in the global market. A study by Freedonia Group highlights that firms investing in superior materials and innovative designs can achieve up to 15% higher market share relative to competitors relying on outdated technologies. Furthermore, rigorous adherence to international standards, such as EN 12810 and EN 12811, not only ensures compliance but also builds trust among clients. Companies focusing on quality improvements often report reduced accident rates—up to 30% fewer incidents—leading to enhanced reputation and client loyalty in an increasingly competitive landscape.

Case studies showcasing the success of ringlock scaffolding in international projects illustrate its versatility and reliability. One notable example comes from a high-rise construction project in Dubai, where the unique design of ringlock scaffolding allowed for rapid assembly and robust support. The project faced challenges with tight deadlines, but the adaptability of the ringlock system enabled the construction team to innovate on-site, reducing labor costs and ensuring safety compliance. The modularity of the scaffolding was key, as it allowed workers to efficiently reposition sections to meet evolving needs without compromising stability.

Another compelling case is seen in a bridge renovation project in Sydney. The ringlock scaffolding system provided critical access to complex areas while accommodating varying heights and loads. This flexibility was crucial in maintaining a seamless workflow, contributing to the project's successful completion within budget and ahead of schedule. The contractors praised the ease of customization and the sturdy nature of the ringlock system, highlighting how it fostered collaboration among teams and kept safety at the forefront, ultimately culminating in a standout example of modern scaffolding in action.