+86 18531742341

+86 18531742341

Leave Your Message

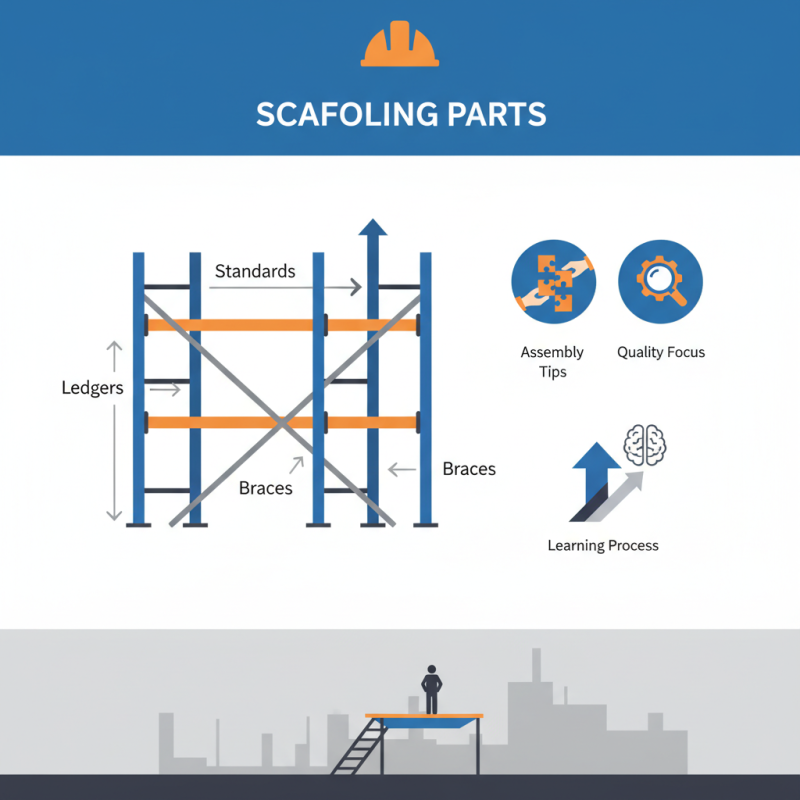

Scaffolding is vital for construction projects. It supports workers and materials safely at height. Beginners may feel overwhelmed by the variety of Scaffolding Parts available. Understanding these parts is crucial for effective use.

The key Scaffolding Parts include standards, ledgers, and braces. Standards provide vertical support, while ledgers form the horizontal framework. Braces ensure stability, preventing swaying or collapse. Beginners should observe common mistakes in assembly. Misplaced parts can lead to accidents, so attention to detail is essential.

When starting out, focus on quality over quantity. Select essential Scaffolding Parts that fit your project. Learning the basics can lead to safer outcomes. Embrace the learning process and don’t hesitate to ask for help. Reflection on practices will improve your skills over time.

When starting with scaffolding, understanding essential parts is crucial. Basic components include frames, braces, and planks. These elements support workers and materials safely. According to a recent industry report, falls account for about 30% of construction injuries. An inadequate scaffolding setup can lead to serious accidents.

Frames serve as the main structure. They support the entire assembly. Braces ensure stability, especially in high winds. Planks are used as walkways. It's vital to choose quality materials. Poor choices here can compromise safety. For instance, using damaged planks increases the risk of collapsing under weight.

Beginners often overlook the importance of inspections. Regular checks can identify wear and tear. A survey indicated that 40% of scaffold-related incidents resulted from poor maintenance. It’s not just about setting up; it's about maintaining security on the job site. Understanding these components and their functions can significantly impact safety and efficiency.

When it comes to scaffolding, safety is a priority for beginners. Always check the stability of your scaffold before use. Inspect all parts, including frames and planks. Look for any signs of wear or damage. Weak components can lead to accidents, so conduct a thorough check.

Tips for beginners: Ensure that your scaffold base is level. This promotes stability and helps prevent tipping. Use toe boards to keep tools and materials from falling. Always wear appropriate safety gear, such as helmets and harnesses. Your safety matters.

Another important safety feature is guardrails. They provide a barrier against falls. Make sure they are installed at all openings. Proper ladder access is essential as well. Use a secure ladder to access higher levels. Never compromise on safety standards, even during tight deadlines. Always prioritize a safe working environment.

| Part Name | Description | Safety Features | Common Uses |

|---|---|---|---|

| Base Plates | Flat plates that provide stability for scaffolding. | Prevents sinking into soft ground. | Used in all scaffolding setups. |

| Standards | Vertical poles that support the scaffolding structure. | Ensure loads are evenly distributed. | Used in various construction projects. |

| Ledgers | Horizontal components connecting standards. | Provides structure support and load distribution. | Supports platform boards. |

| Platform Boards | Walking surface for workers on the scaffolding. | Anti-slip designs available for safety. | Used for access and working areas. |

| Bracing | Diagonal supports that stabilize the scaffold. | Helps prevent swaying and falling. | Used in all types of scaffolding setups. |

When selecting scaffolding for your project, understanding the

different types is crucial. Each scaffolding type serves unique needs and situations. According to industry reports, the

global scaffolding market is projected to reach USD 14.9 billion by 2027, suggesting a growing demand for tailored structural solutions.

Steel scaffolding is well-known for its strength and durability. It's often used for heavy-duty construction jobs.

Aluminum scaffolding is lighter and easier to assemble, making it a favorite for smaller projects or interior work. For residential tasks,

wooden scaffolding offers a classic look but may not withstand harsh weather.

Tip: Always consider the height and weight requirements of your project. Many beginners overlook load capacities.

Ensure your chosen scaffolding type can handle the necessary weight plus additional safety margins.

Another key consideration is mobility. Rolling scaffolds provide the flexibility needed for tasks spanning large areas.

However, they may require more upkeep. Builders should remember that scaffolding maintenance can significantly affect safety.

Regular inspections are vital to prevent accidents and ensure structural integrity.

Tip: Invest in proper training for your team. Many accidents occur from improper setup.

Knowledgeable workers can spot potential issues before they become serious. Always prioritize safety.

When assembling scaffolding, safety should be everyone's top priority. According to the Occupational Safety and Health Administration (OSHA), falls account for about 36% of construction site fatalities. Thus, understanding proper assembly techniques is crucial for beginners.

Before you begin, inspect all parts. Ensure they are free from rust or damage. According to industry guidelines, scaffolding should support four times the maximum intended load. This means every piece must be sturdy and well-maintained. No one wants to find out too late that a plank is weak.

When assembling, always ensure that the base is level. Use wooden planks or leveling devices if necessary. A slanted platform can lead to instability. Additionally, never exceed the height limit recommended for your specific scaffolding type. Many workers overlook this advisory, putting themselves at risk. Being mindful of these details can significantly reduce the chances of accidents on-site. Remember, safety is not just a guideline; it’s a responsibility.

When it comes to scaffolding, regular maintenance and inspection are crucial. A simple visual check every day can catch potential issues. Look for loose bolts or damaged planks. A single crack can compromise the entire structure. Use a notepad to jot down any defects you find. This helps in tracking repairs over time.

Inspecting your scaffolding doesn’t stop at the surface. Check for rust or corrosion underneath the components. Even a small rust spot can lead to major failure. Ensure all safety features are functional. Safety harnesses and guardrails must be secure. Allocate specific times for a thorough inspection, but don’t wait too long if you notice something alarming.

Don’t forget to train your team on proper scaffolding care. Sometimes, they may overlook simple things. A few minutes spent on training can prevent accidents down the line. If an issue arises, hesitate to trust your instincts alone. Consult a professional for serious repairs. This way, you maintain safety and peace of mind.