+86 18531742341

+86 18531742341

Leave Your Message

In the ever-evolving construction industry, the efficiency and safety of scaffolding systems are paramount. Among various scaffolding solutions available, Ringlock Scaffolding Components have emerged as a standard for many construction projects due to their versatility and robust design. According to a report by the Association of Scaffolding Contractors, the adoption of modular scaffolding systems like Ringlock has seen an increase of approximately 30% over the past five years, as contractors seek to enhance productivity while minimizing risk on job sites.

The key elements of Ringlock Scaffolding Components include a unique system that allows for quick assembly and disassembly, making it an ideal choice for projects requiring timely execution and flexibility. With modular design, Ringlock systems facilitate efficient load distribution and improved stability, critical factors in maintaining worker safety. Recent studies indicate that safe scaffolding practices can reduce workplace accidents by as much as 40%, underlining the importance of selecting the right scaffolding components for any construction endeavor.

As we delve further into the essential components of Ringlock Scaffolding, this guide aims to provide comprehensive insights on their functionality, application, and advantages. Understanding these components is crucial for engineers and project managers alike, ensuring that they can make informed decisions that align with industry standards and enhance overall project outcomes.

The Ringlock scaffolding system is renowned for its versatility and strength, making it a preferred choice in various construction projects. At its core, the system is composed of essential components that work together to ensure safety and efficiency. The primary components of a Ringlock scaffolding setup include standards, ledgers, braces, and platforms, each playing a vital role in the overall integrity of the structure.

Standards serve as the vertical elements, providing the main support for the scaffolding. They are typically constructed from robust materials to bear heavy loads. Ledgers, on the other hand, are the horizontal beams that connect the standards and provide structural support and stability. Braces are crucial for preventing lateral movement, ensuring that the scaffolding remains secure and stable under various conditions. Finally, platforms, which provide working surfaces, must be designed for both safety and ease of access, facilitating effective workflow while minimizing the risk of accidents during operation.

Understanding these components is essential for anyone involved in constructing or maintaining a Ringlock scaffolding system. Each part's design and configuration contribute to the overall safety and effectiveness of the scaffolding setup, allowing projects to be completed efficiently while adhering to safety standards. Proper assembly and maintenance of these components are key to achieving a reliable and sturdy scaffolding solution, crucial for the successful execution of construction tasks.

When considering the structural integrity of Ringlock scaffolding, it is crucial to understand the various components that contribute to its overall strength and stability. The Ringlock system is designed with a unique node head that allows for easy connection of vertical and horizontal components, distributing weight evenly and reducing the risk of failure. According to industry reports, properly configured Ringlock scaffolding can support loads ranging from 2,000 to 6,000 pounds per platform, depending on the configuration and materials used. This capability makes Ringlock a reliable choice for diverse construction environments.

Tips for ensuring the maximum structural integrity of Ringlock scaffolding include regular inspections and adherence to load limits. It is essential to check all components for signs of wear and damage before each use. Additionally, scaffolding should always be assembled and disassembled by trained professionals to avoid misconfiguration, which can compromise safety. A recent survey from the Scaffold and Access Industry Association found that 30% of scaffolding accidents stemmed from improper assembly practices, emphasizing the need for rigorous training and strict compliance with safety protocols.

Moreover, consider environmental factors that may impact scaffolding performance. For instance, exposure to high winds or heavy rain can affect stability. Employing wind braces and securing the base with adequate footing can mitigate these risks. Overall, understanding and maintaining the structural integrity of the Ringlock system is essential for the safety and success of any construction project.

When considering the implementation of Ringlock scaffolding, adherence to safety standards is paramount. According to a report by the Occupational Safety and Health Administration (OSHA), falls account for approximately 36% of all construction-related fatalities, highlighting the critical need for compliance with established safety protocols. Ringlock scaffolding, when used correctly, significantly enhances worker safety, thanks to its robust design that allows for greater stability. It is essential for contractors to familiarize themselves with the relevant safety standards such as AS/NZS 1576.3 or EN 12810-1, which outline the necessary requirements for scaffolding solutions in various environments.

Compliance with these standards not only aids in safeguarding workers but also reduces liability for contractors. A study from the Scaffold Industry Association notes that proper training and adherence to standards can reduce scaffold-related accidents by up to 50%. In addition, thorough inspections and maintenance of scaffolding components contribute to safe construction practices. Ensuring that workers are trained to recognize potential hazards and understand the importance of using compliant equipment is an effective strategy to foster a culture of safety on job sites. The investment in safety standards and compliance ultimately pays off, protecting both personnel and the project’s overall integrity.

| Component | Description | Safety Standards | Compliance |

|---|---|---|---|

| Standard Ledger | Horizontal members that connect the vertical posts. | EN 12811-1 | Must adhere to national and local regulations. |

| Vertical Standards | Vertical elements providing support for the scaffolding. | ISO 9001 | Regular inspections required for compliance. |

| Diagonal Brace | Supports the structure against lateral forces. | BS 1139-2 | Periodic stability tests recommended. |

| Base Jack | Adjustable base for leveling and support. | OSHA Standards | Must be used as per manufacturer guidelines. |

| Ringlock Fittings | Connects various scaffolding components securely. | EN 1004 | Compliance required for structural integrity. |

When it comes to scaffolding systems, the choice between Ringlock scaffolding and other types is crucial for the efficiency and safety of construction projects. Ringlock scaffolding is renowned for its versatility and strength, which are essential attributes in scaffolding. According to the Global Scaffolding Market Report, the Ringlock system accounts for approximately 35% of the market share due to its unique design that allows for easy assembly and disassembly, facilitating faster project completion times.

In comparison to traditional scaffolding systems like tube and clamp, Ringlock boasts several advantages. Its modular design not only reduces the number of components required but also enhances stability through its locking mechanism, which distributes weight evenly. A study from the International Journal of Construction Management emphasizes that Ringlock systems reduce labor costs by up to 25% due to quicker installation times. Additionally, the robust nature of Ringlock scaffolding contributes to a safer working environment, with incidents of scaffold-related injuries decreasing by nearly 30% when utilizing this system over its counterparts.

Moreover, while systems like modular scaffolding may offer ease of use, they often lack the adaptability of Ringlock in complex structures. The same market analysis indicates that projects using Ringlock scaffolding reported a 15% improvement in logistical efficiency, mainly due to the reduced need for extensive planning and adjustments on-site. Thus, selecting Ringlock scaffolding not only enhances project execution but also promotes a safer workplace, providing valuable long-term benefits in the construction industry.

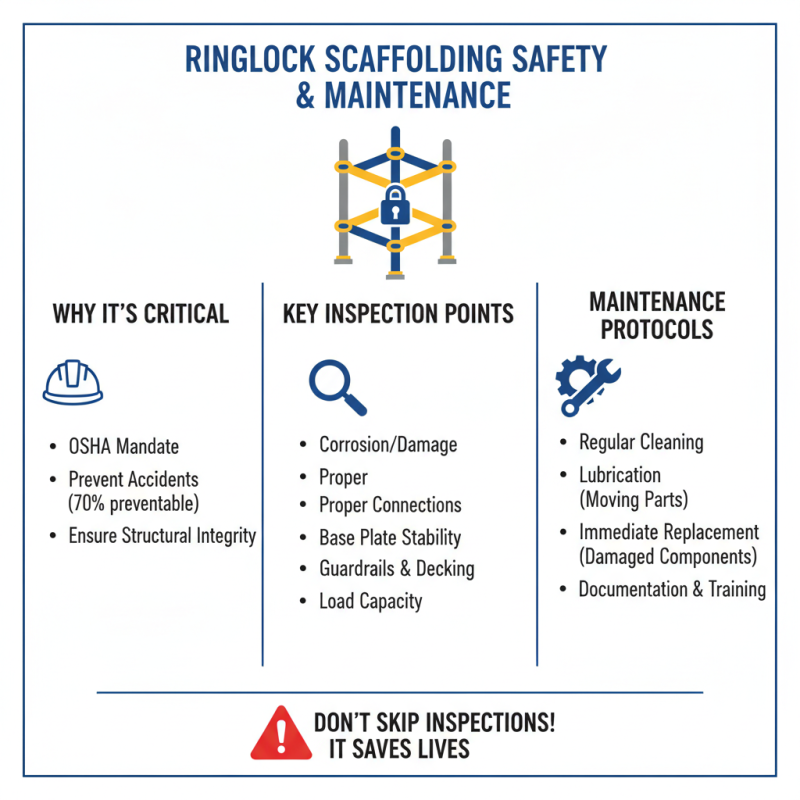

When it comes to ensuring safety and functionality in construction projects, the maintenance and inspection of Ringlock scaffolding components are paramount. According to the Occupational Safety and Health Administration (OSHA), improper scaffolding can lead to serious accidents, making regular inspections critical. A comprehensive inspection routine should assess the integrity of the scaffolding, including checking for corrosion, proper connections, and structural stability. Reports indicate that nearly 70% of scaffold-related accidents can be traced back to inadequate maintenance and inspection protocols, underscoring the importance of diligent practices.

Moreover, adhering to systematic maintenance schedules will not only extend the lifespan of the Ringlock scaffolding but also enhance worker safety on site. A survey from the National Institute for Occupational Safety and Health (NIOSH) reveals that scaffolding maintained on a scheduled basis reduces the risk of collapse and failure by up to 20%. Proper cleaning, storage, and repairs of individual components, such as standards, ledgers, and transoms, are essential to mitigate wear and degradation. Project managers should emphasize training for workers on how to properly inspect and report issues to ensure that every part of the scaffolding system remains in optimal condition throughout the project lifecycle.