+86 18531742341

+86 18531742341

Leave Your Message

In the realm of construction, safety and efficiency are paramount, and one of the key elements that contribute to both is the use of high-quality scaffolding. Among the various types of scaffolding systems available, Ringlock scaffolding has gained prominence due to its versatility and robustness. Understanding the importance of Ringlock scaffolding components is essential for contractors and construction managers aiming to optimize their projects. These components not only ensure structural integrity but also facilitate swift assembly and disassembly, making them an invaluable asset on any job site.

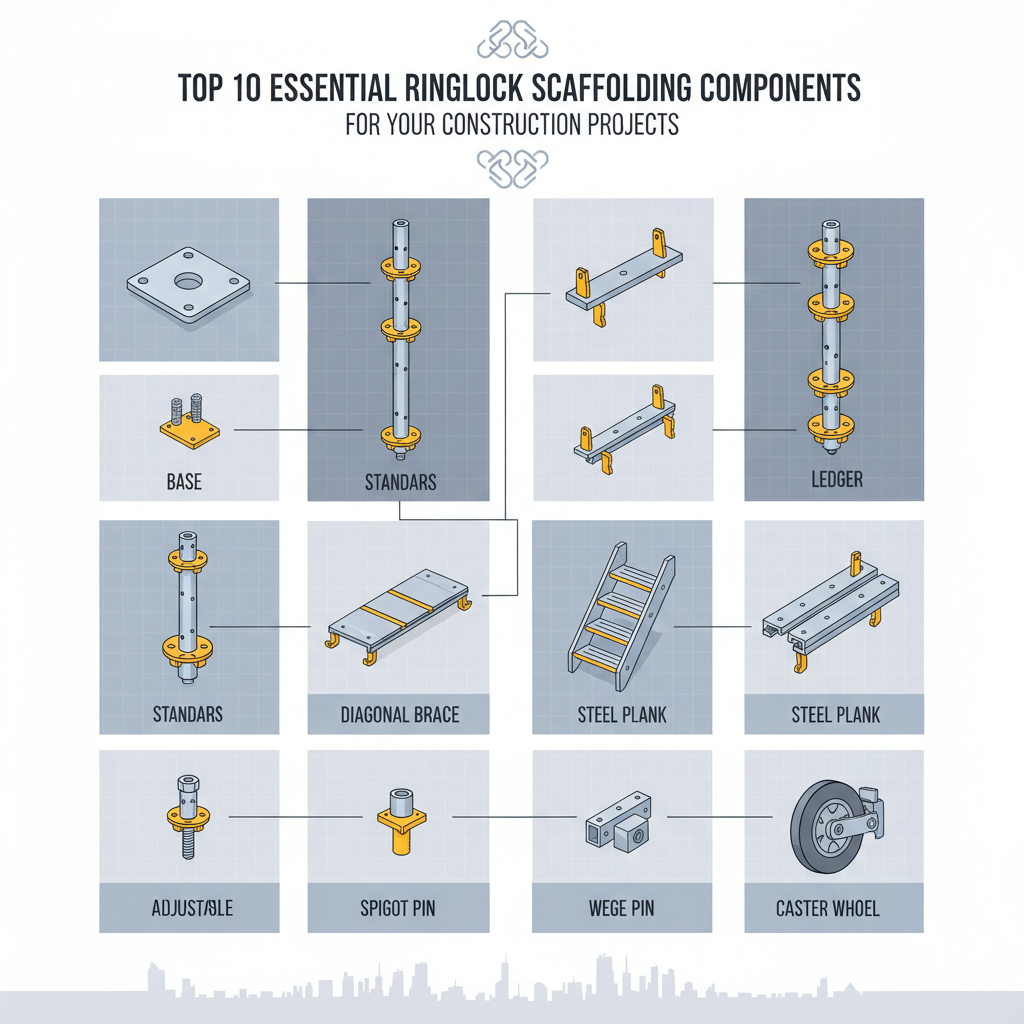

As we delve into the top 10 essential Ringlock scaffolding components, we will explore how each element plays a pivotal role in enhancing the overall scaffold system. From the base plates to the locking pins, each component is designed to interlock securely, providing a stable platform for workers and materials alike. The right combination of these components can significantly impact the success of construction projects, ensuring that safety regulations are met while also improving workflow efficiency. Join us as we highlight the crucial components that every construction professional should consider when opting for Ringlock scaffolding in their projects.

Ringlock scaffolding is a modular scaffold system that offers a robust and versatile solution for construction projects. The key to its effectiveness lies in its essential components, each designed to enhance stability, safety, and ease of assembly. Among these components, the standard, ledger, and diagonal brace are fundamental. The standard serves as the vertical support, providing height and strength, while the ledger connects horizontal structures, ensuring the scaffolding remains uniformly stable. Diagonal braces provide additional stability by creating triangular support, effectively distributing loads and preventing wobbling.

Another crucial component is the platform, which provides a working surface for laborers. These platforms can be composed of plywood, steel, or aluminum, depending on the specific requirements of the project. Coupled with base plates and screw jacks, which help to level the scaffolding on uneven ground, these elements ensure a secure foundation. Additionally, safety guardrails are vital for protecting workers from falls, making them indispensable in any application of ringlock scaffolding. Understanding these essential components is vital for maximizing efficiency and maintaining safety on construction sites.

Ringlock scaffolding is known for its versatility and strength, making it an essential choice in construction projects. Each component plays a crucial role in ensuring both safety and efficiency on-site. For instance, the vertical standards provide the primary support and are designed to handle heavy loads, allowing workers to operate at various heights securely. Additionally, the horizontal ledgers connect standards horizontally, offering stability and creating a solid platform for workers to perform their tasks.

Other vital components include the diagonal braces, which enhance the overall structural integrity by preventing swaying and lateral movement, and the platform boards, which provide a safe working surface for laborers. Couplers and pins are also fundamental, as they facilitate easy assembly and disassembly, reducing time spent on scaffolding setup. The design of ringlock scaffolding allows for quick adjustments and configurations, making it an ideal choice for evolving project needs. Each component not only contributes to the scaffolding system's strength but also maximizes safety, allowing construction projects to proceed smoothly and efficiently.

When selecting scaffolding systems for construction projects, it's essential to understand how Ringlock scaffolding compares to other popular options. Ringlock scaffolding offers a unique design characterized by its efficient connection system, which allows for rapid assembly and disassembly. Unlike traditional tube and clamp systems, Ringlock scaffolding provides added stability and strength, making it ideal for various construction environments. This system minimizes the need for additional components, thus reducing the overall weight and complexity of scaffolding structures.

**Tips:** When choosing scaffolding, consider the specific needs of your project, such as the height and load requirements. Ringlock scaffolding is particularly designed for adaptability, making it suitable for both small-scale jobs and large commercial projects. Additionally, always explore safety features, as Ringlock scaffolding is known for its secure locking mechanism that enhances worker safety.

In contrast, systems like frame scaffolding are often simpler and more cost-effective for short-term use but may lack the robustness and flexibility found in Ringlock scaffolding. For projects that require extended duration and heavy-duty applications, investing in Ringlock scaffolding can provide significant long-term benefits, including durability and ease of maintenance.

Safety considerations are paramount when using ringlock scaffolding, particularly in light of recent tragedies that highlight the potential dangers associated with inadequate safety measures. The devastating fire in Hong Kong, which was preceded by numerous safety complaints from residents about flammable materials and unsafe scaffolding practices, serves as a stark reminder of the crucial need for rigorous safety standards in construction projects. Ensuring that scaffolding components are compliant with safety regulations can mitigate risks, protecting workers and the public alike.

When utilizing ringlock scaffolding, it is essential to conduct thorough inspections of all components, including the integrity of the connections and the suitability of the materials used. In environments where fire hazards exist, like in renovation works or high-density residential areas, scaffolding should be secured and monitored proactively. Training and educating crews on the importance of safety protocols and hazard awareness can greatly reduce the likelihood of incidents, similar to those that occurred in recent high-profile cases. By prioritizing safety and adhering to best practices, the construction industry can work toward preventing catastrophic events and ensuring the safety of all involved.

| Component | Description | Key Safety Considerations |

|---|---|---|

| Standards | Vertical members that support the scaffolding system. | Ensure proper installation and load-bearing capacity. |

| Braces | Provide lateral stability to the scaffold structure. | Check for secure fastening to prevent swaying. |

| Transoms | Horizontal members that support the decking. | Verify alignments to prevent slip-offs. |

| Decking | Platforms where workers stand and perform tasks. | Inspect for damage and ensure proper load limits are adhered to. |

| Footings | Base supports that help distribute load. | Ensure they are placed on stable ground. |

| Guardrails | Safety barriers to prevent falls from height. | Install according to height safety standards. |

| Couplers | Connect different components of the scaffolding system. | Ensure tight connections to avoid disconnections. |

| Access Ladders | Provide access to different scaffold levels. | Securely attach and check for stability before use. |

| Tie Bars | Horizontal members used to stabilize vertical standards. | Properly tension and secure for optimal stability. |

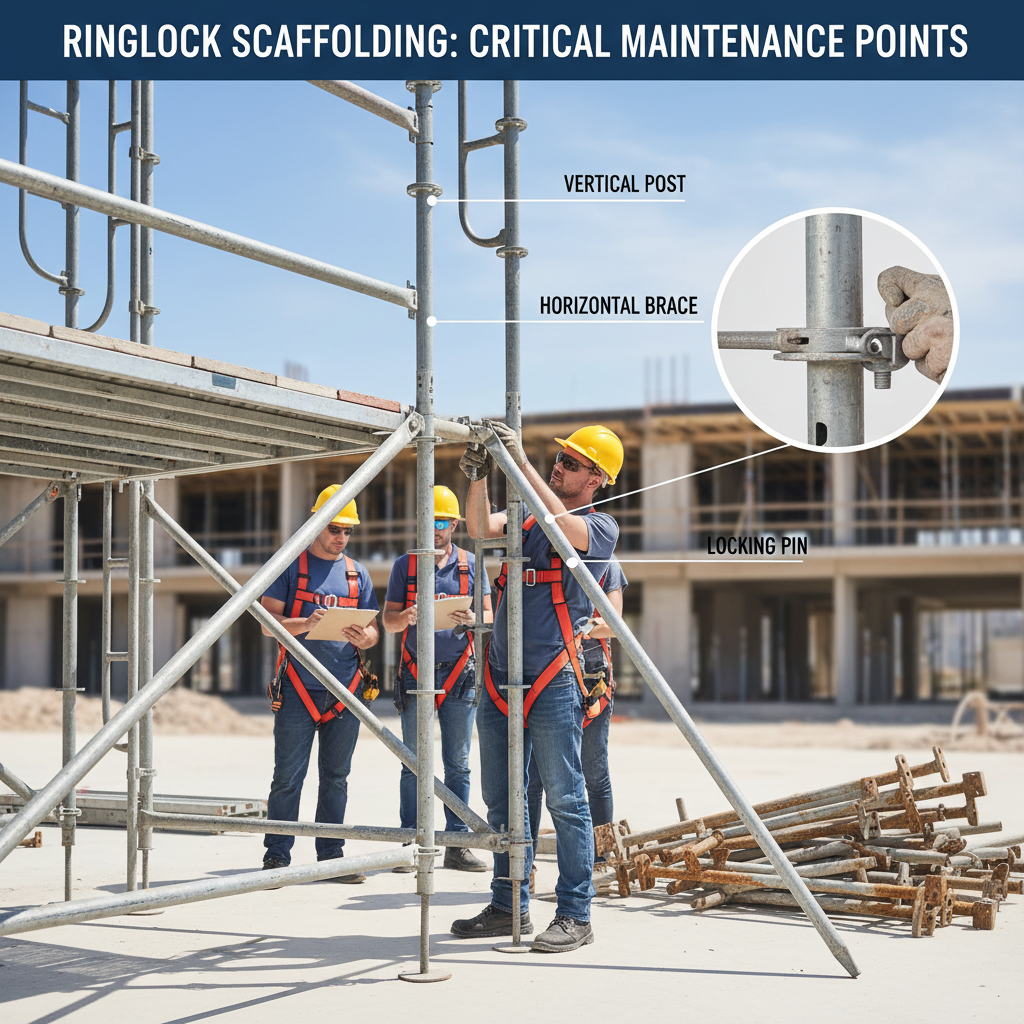

Proper maintenance of Ringlock scaffolding components is vital for ensuring their longevity and reliability on construction sites. Regular inspections should be conducted to detect any signs of wear, corrosion, or damage. Components such as vertical posts, horizontal braces, and locking pins are especially susceptible to stress and should be thoroughly examined. Any parts showing significant wear should be replaced immediately to prevent potential failures that could compromise worker safety.

In addition to routine inspections, it is important to clean the scaffolding components regularly. Dirt, debris, and contaminants can lead to corrosion and deterioration over time. Using mild detergents and a soft brush helps maintain the integrity of the steel, while avoiding harsh chemicals that could cause damage. Furthermore, it is advisable to store unused components in a dry, protected area to shield them from moisture and environmental factors that can accelerate wear. Implementing these maintenance tips will ensure that your Ringlock scaffolding remains in optimal condition, ultimately enhancing both safety and efficiency on your construction projects.