+86 18531742341

+86 18531742341

Leave Your Message

In the ever-evolving construction industry, the demand for robust and reliable scaffolding solutions is paramount. According to a report by Research and Markets, the global scaffolding market is projected to reach $66 billion by 2027, underscoring the critical role that scaffolding, particularly scaffolding pipes, play in maintaining safety and efficiency on job sites. As construction projects become increasingly complex and demanding, the focus on quality materials has intensified. Chinese manufacturers have emerged as key contributors, providing scaffolding pipes that comply with international standards, thereby enhancing overall project outcomes. This blog will delve into the essential checklist for evaluating the quality of scaffolding pipes, ensuring that construction professionals can make informed decisions that elevate global standards in the industry.

The rise of Chinese-made scaffolding pipes in the global market is a testament to the aggressive manufacturing capabilities and innovations emerging from China. According to a recent report by Research and Markets, the global scaffolding market is projected to reach approximately $65 billion by 2025, with a significant portion attributed to the increasing demand for safe and reliable scaffolding solutions. China, being the largest producer and exporter of scaffolding materials, is strategically positioned to meet this demand with affordable yet high-quality products.

Chinese scaffolding pipes, particularly those adhering to international standards like ASTM and EN, are gaining recognition for their durability and structural integrity. A report from Allied Market Research highlights that the quality of scaffolding products made in China has seen improvement, driven by advancements in manufacturing techniques and stringent quality control processes. This shift not only enhances the reputation of Chinese manufacturers but also reassures construction companies globally that they can depend on locally sourced materials without compromising safety or efficiency. As Chinese-made scaffolding pipes continue to penetrate international markets, they are setting new benchmarks for quality in the construction industry.

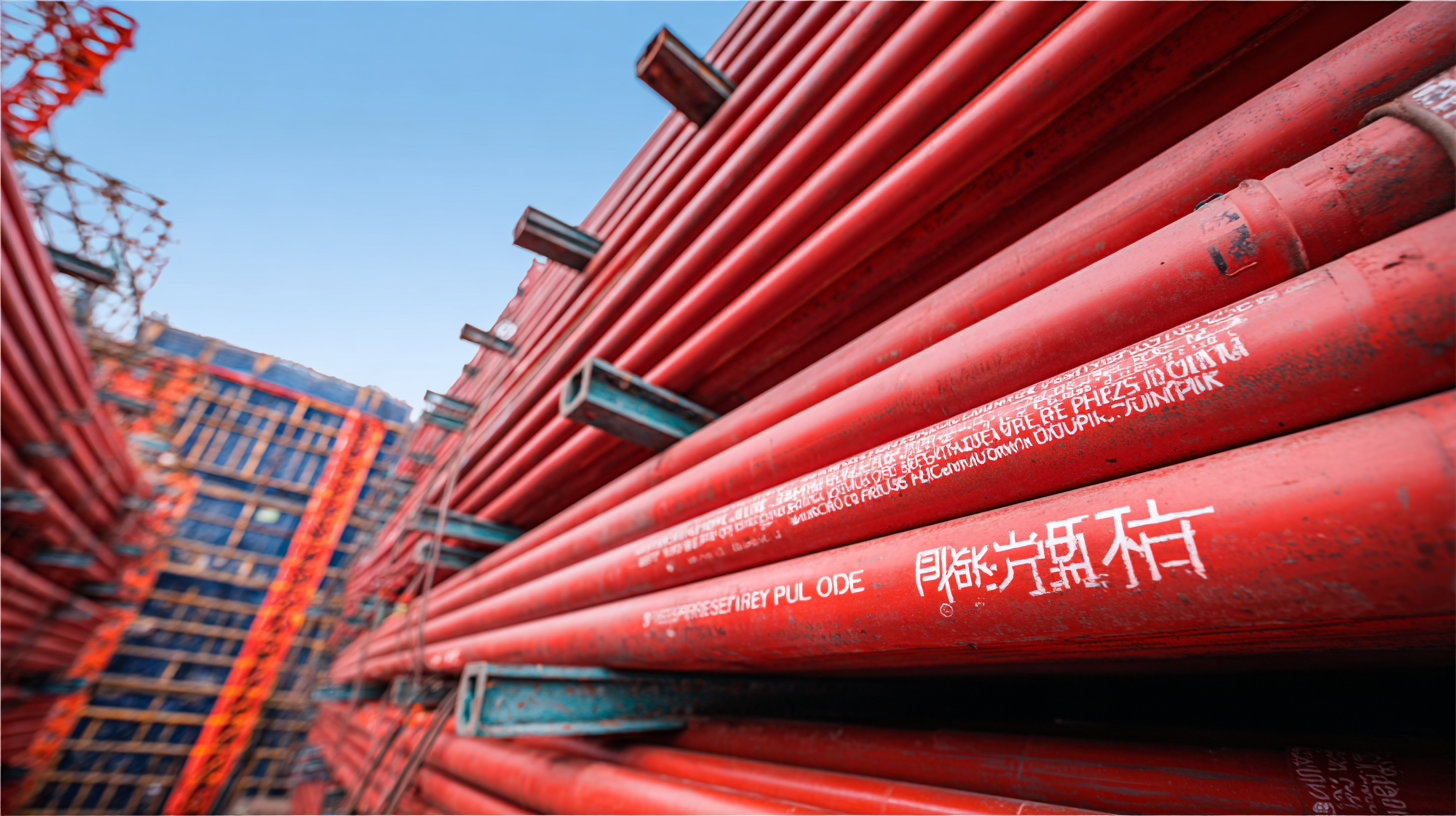

When it comes to scaffolding, the importance of quality cannot be overstated. High-quality scaffolding pipes from China are emerging as a benchmark in the industry, combining resilience and versatility. Engineered from premium-grade materials, these pipes are designed to endure the rigors of construction while ensuring safety and stability. Their rust-resistant coatings enhance durability, making them suitable for various environmental conditions, which is crucial for long-term projects.

When it comes to scaffolding, the importance of quality cannot be overstated. High-quality scaffolding pipes from China are emerging as a benchmark in the industry, combining resilience and versatility. Engineered from premium-grade materials, these pipes are designed to endure the rigors of construction while ensuring safety and stability. Their rust-resistant coatings enhance durability, making them suitable for various environmental conditions, which is crucial for long-term projects.

Another key feature of these scaffolding pipes is their precise engineering and manufacturing processes. Advanced technology is employed to ensure each pipe meets international standards for strength and load-bearing capacity. This results in scaffolding systems that are not only strong but also lightweight, facilitating easier handling and installation on-site. Additionally, strict quality control measures during production further guarantee that each piece functions flawlessly, contributing to overall worker safety and project efficiency. This commitment to excellence positions Chinese-made scaffolding pipes as a top choice for construction professionals worldwide.

The rise of Chinese manufacturing has revolutionized many industries, and scaffolding is no exception. Chinese scaffolding pipes are increasingly recognized for their high quality, durability, and cost-effectiveness, playing a pivotal role in enhancing global safety standards in construction. These pipes undergo rigorous testing and quality control processes, ensuring that they meet international standards. As a result, construction sites utilizing Chinese scaffolding products experience fewer accidents and enhanced structural integrity.

One of the key factors contributing to the safety of Chinese-made scaffolding pipes is their compliance with established safety protocols. By utilizing advanced materials and innovative manufacturing techniques, these pipes provide exceptional strength and stability, which are critical for construction projects involving multiple stories or complex structures. Furthermore, manufacturers often invest in cutting-edge technology to continuously improve their products, ensuring that they not only meet but exceed global requirements. This commitment to safety is vital for contractors and workers alike, reinforcing the importance of reliable scaffolding in minimizing risks on construction sites.

Chinese scaffolding pipe manufacturing is at the forefront of innovation, integrating advanced technologies that redefine quality and safety standards in the construction industry. By leveraging cutting-edge techniques such as automated welding, precision cutting, and advanced materials science, manufacturers are delivering products that meet and exceed global expectations. These innovations not only enhance the structural integrity of scaffolding systems but also improve their durability and ease of use, ensuring that construction projects can proceed safely and efficiently.

Furthermore, the implementation of digital technologies, such as IoT (Internet of Things) and AI (Artificial Intelligence), has transformed the way scaffolding pipes are designed and manufactured. Smart factories enable real-time monitoring of production processes, allowing for rapid adjustments and quality control. This results in a standardized product line that consistently meets international safety regulations. As Chinese manufacturers continue to invest in research and development, the scaffolding pipe sector is set to achieve new heights, providing the construction industry with superior solutions that emphasize safety, reliability, and performance.

The scaffolding industry is witnessing a significant shift as Chinese manufacturers continue to elevate global standards with their high-quality scaffolding pipes. A comparative analysis between Chinese scaffolding pipes and their global competitors reveals that the rigorous manufacturing processes in China yield superior durability and reliability. This is particularly important as the scaffolding market is projected to grow from USD 55.12 billion in 2024 to USD 75.9 billion by 2032, reflecting a compound annual growth rate (CAGR) of 4.4% from 2025 to 2032.

This growth trajectory aligns with the booming demand for construction materials, where scaffolding accessories are also expected to see steady growth. According to recent reports, the global rubber compound market is set to exceed USD 15.69 billion by 2030, underscoring the interconnected nature of these sectors. As the construction industry expands, the need for high-quality scaffolding solutions becomes increasingly critical, allowing Chinese-made scaffolding pipes to occupy a significant competitive edge in both domestic and international markets.