+86 18531742341

+86 18531742341

Leave Your Message

Cup Lock Scaffolding has gained significant attention in the construction industry for its efficiency and structural integrity. According to a recent report by MarketsandMarkets, the global scaffolding market is projected to reach $4.5 billion by 2027, with Cup Lock systems identified as a key driver due to their ease of installation and versatility. This system offers robust support for different types of construction projects, significantly impacting safety and productivity.

Despite its advantages, Cup Lock Scaffolding is not without challenges. Workers must be adequately trained to assemble and disassemble the system. Mishandling during setup can lead to safety risks. Furthermore, while Cup Lock Scaffolding is designed for stability, it requires thorough inspection and maintenance. Inadequate checks can result in unforeseen failures. The industry must emphasize not just compliance, but proactive measures to ensure worker safety and structure reliability.

In a landscape driven by efficiency, Cup Lock Scaffolding meets the evolving demands of modern construction. Yet, it is crucial to reflect on its limitations and continuously seek improvements. Balancing speed and safety remains a persistent challenge for this widely used system.

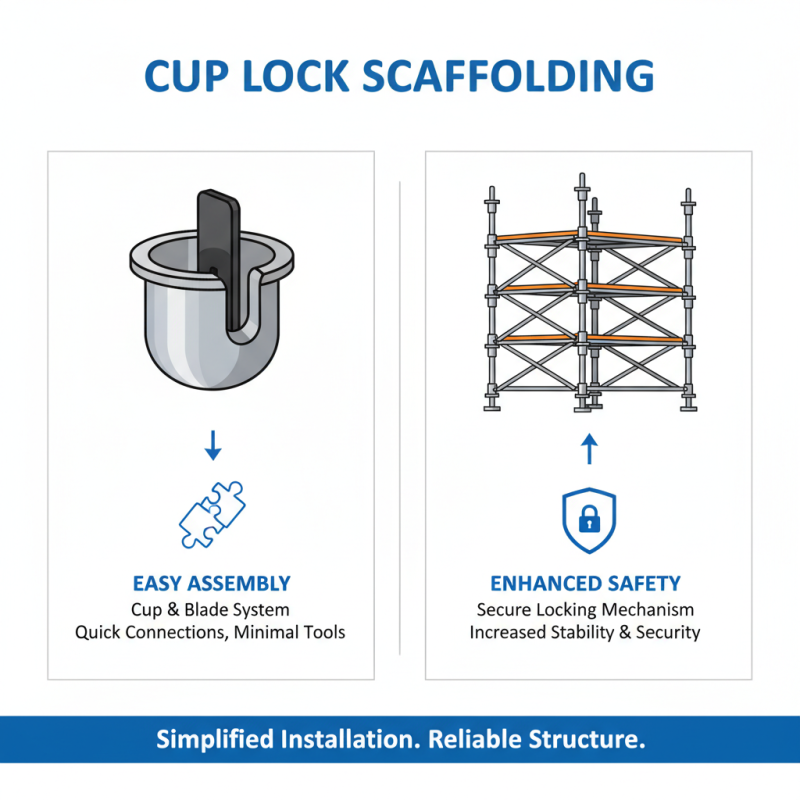

Cup lock scaffolding is an innovative form of scaffolding widely used in construction. It features a unique cup and blade connection system. This design allows for quick assembly and disassembly, making it popular among contractors. The scaffolding consists of vertical standards, horizontal braces, and diagonal supports.

Each standard has adjoining cups at specific intervals. Workers can easily insert horizontal members into these cups. This method creates a stable structure. The load-bearing capacity is significant, which enhances safety on job sites. It is crucial to ensure that all components are correctly installed.

However, some users may struggle with alignment at times. Not positioning properly can lead to weak structures. Regular inspections are necessary to maintain safety standards. While it is a robust system, it demands attention to detail. This vigilance can prevent accidents during operation.

| Aspect | Details |

|---|---|

| Definition | Cup lock scaffolding is a versatile scaffolding system using a unique locking mechanism for fast and effective assembly and disassembly. |

| Components | Standard, ledgers, cups, braces, and base plates. |

| Mechanism | Utilizes a cup and spigot system where spigots fit into cups for solid connections between components. |

| Advantages | Quick assembly, stability, and high load-bearing capacity. |

| Applications | Used in construction, maintenance, and renovation projects. |

| Safety Features | Includes guardrails and debris nets to enhance occupational safety. |

| Weight | Lightweight components are easy to transport and handle. |

| Disassembly | Easy to disassemble without the need for special tools. |

Cup Lock scaffolding is a popular choice in construction due to its versatility. The key components include vertical standards, horizontal ledgers, and cup lock connections. The vertical standards are the main support, holding the structure steady. They come in various heights to cater to different building requirements.

The horizontal ledgers connect the vertical standards. These pieces support the platform on which workers stand. The cup lock connection systems ensure stability and strength. They consist of cups welded to the vertical pipes, allowing for quick setup. This design minimizes the risk of collapse during use.

Tips for using Cup Lock scaffolding: Always check each component for damage before assembly. Proper inspection can save lives. Ensure correct assembly to avoid accidents. Improper installation can lead to significant safety hazards.

Over time, wear and tear can occur. Regular maintenance is crucial. Sometimes, components may not fit perfectly, requiring adjustments. Address these issues before they escalate. Noticing small problems early on can prevent larger failures later.

Cup lock scaffolding is a popular choice in construction due to its simplicity and efficiency. Assembling this type of scaffolding is straightforward but requires precision. The key components include vertical posts and horizontal ledgers, which are connected using cup locks. The cup locks consist of a series of cups and spigots that allow for quick connections between parts. This design enables workers to create a sturdy framework quickly.

To assemble cup lock scaffolding, start with the vertical posts. Position them upright and ensure they are level. Next, insert the horizontal ledgers into the cups at various heights. Make sure they fit securely. It is essential to check each joint for stability as you go along. Missing a cup lock can lead to instability, which might compromise safety. Workers often overlook this during hurried setups.

Adding diagonals or braces strengthens the structure further. Although it may seem tedious, double-checking each connection is vital. An assembly that looks good may not always function well. Emphasizing attention to detail can prevent accidents. Quality control should not be an afterthought in construction. Scaffolding must provide both safety and efficiency on site.

Cup Lock scaffolding is designed for easy assembly and enhanced safety. It utilizes a unique cup and blade system that allows quick connections. This system simplifies the installation process. Workers can set up and dismantle the scaffolding with minimal tools. The locking mechanism ensures stability, which adds a layer of security.

One significant benefit is its versatility. Cup Lock scaffolding can adapt to various construction needs. It suits both small projects and large-scale buildings. This adaptability can save time and resources. Reinforced components also increase its durability. However, some workers find the setup challenging without proper training. Proper knowledge is key to maximize its potential.

Additionally, the space-efficient design allows for easier manipulation on-site. Workers benefit from working at different levels without complex adjustments. This can accelerate construction timelines. Yet, with all its advantages, safety training remains crucial. It’s vital to address any concerns among the crew. This ensures everyone feels confident while using this scaffolding system.

Cup lock scaffolding provides a stable platform for construction work. While it is effective, safety should always be a priority. Understanding the proper safety measures is crucial for avoiding accidents.

One key consideration is the inspection of the scaffolding before use. Check for loose parts and rust. A damaged component could lead to failure under weight. Ensure workers are aware of their surroundings. Crowded sites increase risk. Proper training is necessary for all personnel to recognize hazards.

**Tips:** Always wear a hard hat on the job site. This simple measure protects against falling objects. Use guardrails whenever possible. They provide additional safety when working at heights. A clear communication system among team members is essential. Misunderstandings can lead to serious accidents. It's critical to foster a culture of safety, where everyone feels responsible.