+86 18531742341

+86 18531742341

Leave Your Message

As we look ahead to 2025, the field of construction scaffolding is poised for significant advancements and shifts. According to industry expert John Harrison, "The future of construction scaffolding lies in our ability to innovate while ensuring safety and efficiency." With a growing emphasis on sustainability and technology, the scaffolding sector is embracing new materials and methods that promise to enhance worksite effectiveness and environmental responsibility.

In the coming years, trends such as the integration of smart technology, modular designs, and eco-friendly materials will reshape the landscape of construction scaffolding. These innovations are not only improving safety measures but also optimizing the scaffold assembly process, making it faster and more efficient. As we delve into the prominent trends that will define construction scaffolding in 2025, we will explore how these changes can lead to increased productivity and improved standards within the industry.

The evolution of construction scaffolding reflects broader changes within the construction sector itself, as companies seek to adapt to new challenges and opportunities. By staying informed about these key developments, industry professionals can better position themselves for success in an evolving marketplace.

As construction projects evolve, emerging technologies in scaffolding are playing a pivotal role in enhancing structural safety. Innovations such as smart scaffolding systems equipped with sensors allow for real-time monitoring of structural integrity. These systems can detect shifts, cracks, or pressure changes, providing instant alerts to site managers. This data-driven approach not only mitigates risks but also contributes to overall efficiency, enabling timely interventions that prevent accidents and damage.

Additionally, the integration of advanced materials, such as lightweight composites and modular components, is transforming traditional scaffolding practices. These materials not only improve the overall strength-to-weight ratio but also facilitate quicker assembly and disassembly processes. By reducing the time scaffolding is in place, these technologies help minimize disruptions on site and optimize safety protocols. Enhanced worker safety features, such as integrated guardrails and non-slip surfaces, further support the goal of creating a safer working environment on construction sites in 2025 and beyond.

| Trend | Description | Impact on Safety | Implementation Timeline |

|---|---|---|---|

| Smart Scaffolding | Integration of IoT devices for real-time monitoring of scaffold integrity. | Enhanced stability and early detection of potential failures. | Q2 2025 |

| Modular Scaffolding Systems | Use of prefabricated modular components to increase speed and adaptability. | Improved load distribution reduces structural failures. | Q1 2025 |

| Drones for Inspection | Use of drones for detailed inspections and monitoring of scaffolding structures. | Reduced human risk during inspections and improved identification of issues. | Mid 2025 |

| Robotics in Assembly | Implementation of robotic systems for assembling and disassembling scaffolding. | Minimized risk of accidents during assembly, enhancing worker safety. | Late 2025 |

As the construction industry moves toward greater sustainability, scaffolding is undergoing a significant transformation driven by the use of eco-friendly materials. According to a recent report by Research and Markets, the global green construction market is expected to reach $1.4 trillion by 2025, with sustainable scaffolding playing a pivotal role in this growth. Materials like recycled steel, aluminum, and bio-based polymers are increasingly being utilized, significantly reducing the carbon footprint associated with traditional scaffolding solutions. These advancements not only enhance structural integrity but also mitigate environmental impact, making scaffolding more sustainable.

Additionally, the implementation of innovative materials is revolutionizing scaffolding design and usage. A study from MarketsandMarkets emphasizes that the adoption of modular scaffolding systems, which leverage lightweight and durable materials, can reduce assembly times by up to 30%. This efficiency is crucial as construction projects demand faster timelines while maintaining safety standards. Furthermore, sustainable practices in materials sourcing and lifecycle management are proving beneficial, as firms strive to meet both regulatory demands and client expectations for greener projects. This shift highlights the industry's commitment to balancing operational efficiency with environmental responsibility, setting the foundation for future scaffolding trends.

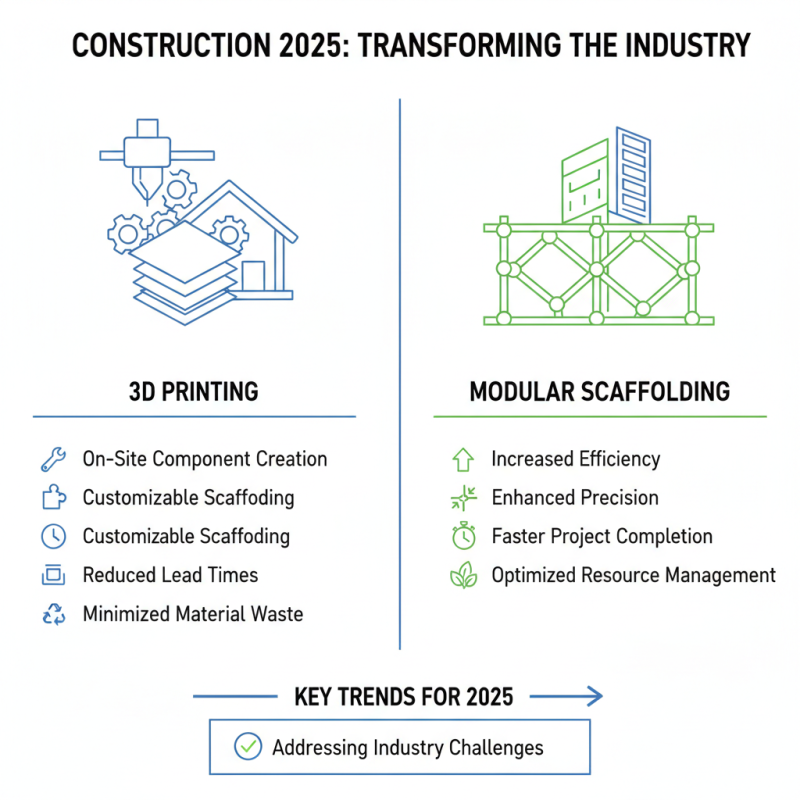

The construction industry is on the brink of a transformative shift as 3D printing and modular scaffolding emerge as key trends for 2025. By integrating 3D printing technology, construction sites can achieve unprecedented levels of efficiency and precision. This innovative approach enables the creation of customizable scaffolding components on-site, reducing lead times and minimizing material waste. As a result, projects can be completed faster, and resource management can be optimized, addressing some of the industry's longest-standing challenges.

Modular scaffolding systems complement the advancements in 3D printing by offering adaptable and reusable structures. These systems can be pre-fabricated off-site, allowing for swift assembly and disassembly on location, which not only enhances safety but also accelerates project timelines. The combination of 3D printing and modular scaffolding is paving the way for a more sustainable construction model, where flexibility and efficiency are prioritized. This synergy not only supports the growing demand for faster builds but also aligns with environmental goals, demonstrating the potential to reshape how construction projects are managed in the future.

The construction industry is on the verge of a significant transformation, with automation and robotics leading the charge in scaffolding assembly processes. As projects become more complex and time-sensitive, the adoption of robotic systems is streamlining operations and enhancing safety on worksites. These advancements allow for precise measurements and adjustments, reducing human error and the risks associated with manual assembly. Robotic arms and drones are increasingly used to set up scaffolding structures, enabling quicker assembly times and minimizing the need for extensive labor crews.

Moreover, the integration of automation technologies is reshaping project management and workflow optimization. Construction teams can now use automated systems for monitoring and managing scaffolding installations, ensuring that safety standards are met while also cutting down on costs.

The use of advanced software and AI-driven analytics helps in planning and executing scaffolding setups more efficiently. As these technologies evolve, they promise to further revolutionize the scaffolding industry, paving the way for more sustainable practices and improved productivity in construction projects worldwide.

Regulatory changes are poised to significantly impact scaffolding practices in the construction industry by 2025. As safety standards evolve, construction companies will need to adapt their scaffolding systems to comply with new regulations that emphasize worker safety and environmental sustainability. Anticipated regulations may require enhanced inspections, maintenance protocols, and the use of materials that minimize environmental impact. Companies that embrace these changes early will not only ensure compliance but also enhance their reputation by prioritizing safety and sustainability.

Furthermore, regulatory bodies are increasingly focusing on the training and certification of scaffolding workers. New rules may mandate that all personnel handling scaffolding equipment undergo rigorous training programs designed to equip them with the knowledge of proper assembly, disassembly, and safety measures. This shift towards mandatory training is aimed at reducing accidents on construction sites and ensuring that workers are well-versed in the latest scaffolding technologies and safety practices. As a result, construction firms will need to invest in ongoing training initiatives, fostering a culture of safety and compliance that aligns with regulatory expectations.