+86 18531742341

+86 18531742341

Leave Your Message

In the world of construction, choosing the right scaffolding parts is crucial. John Thompson, a renowned scaffolding expert, states, "Quality scaffolding parts save both time and money." Selecting the best components ensures safety and efficiency on any project. However, many workers overlook this essential step.

When it comes to scaffolding parts, understanding the specific needs of your project is key. Each project has unique requirements. For instance, urban settings may require lighter, more portable materials. Meanwhile, heavy-duty constructions call for robust and durable options. Ignoring these details can lead to unsafe working conditions.

It’s easy to think that all scaffolding parts are the same—this can be a mistake. Different projects demand different specifications. Additionally, evaluating the quality of materials can be challenging. Workers often face pressure to cut costs, but this can backfire. Wise choices in scaffolding parts can prevent accidents and project delays.

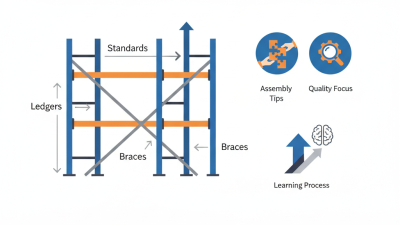

When selecting scaffolding components, understanding the types is crucial. Scaffolding parts generally include frames, planks, and braces. Each component serves a distinct purpose and should fit your project's requirements. For example, frames provide the structure. They come in various heights and widths. Choosing the right size can impact both stability and accessibility.

Planks are vital for worker safety. They offer a platform to stand on. Look for materials that provide a good grip and are resistant to rot. Some planks don’t meet safety standards. Always verify their condition before use.

Braces are another key component. They stabilize the structure. Without proper bracing, scaffolding can become unstable. Many people forget to check braces regularly. This oversight can lead to serious safety issues. Always assess each component carefully. Regular maintenance is essential for a successful project.

| Component Type | Material | Weight Capacity | Common Uses | Height |

|---|---|---|---|---|

| Standard | Steel | 2,500 lbs | Construction | 10 ft |

| Brace | Aluminum | 1,500 lbs | Stabilization | N/A |

| Platform | Plywood | 1,200 lbs | General Access | 8 ft |

| Ledger | Steel | 3,000 lbs | Support Framework | 12 ft |

| Transom | Aluminum | 1,800 lbs | Cross Support | 6 ft |

When evaluating quality and safety standards for scaffolding parts, consider multiple factors. Look for materials that are durable and reliable. Steel parts usually provide strength. Aluminum can offer lightweight options. Always check for compliance with safety regulations. This ensures that the scaffolding will hold up under stress.

**Tip:** Inspect each part for any visible wear. Cracks or rust can indicate weak spots. Even small damages can lead to catastrophic failures.

Safety features are crucial in scaffolding. Look for guardrails and safe access points. These reduce the risk of falls and accidents. Regular maintenance checks can help catch issues early. It’s also wise to consult safety standards in your area.

**Tip:** Keep a maintenance log. Understanding the lifespan of parts can help in decision-making. Note what works and what doesn’t for future projects.

When selecting scaffolding parts, assessing load capacity and durability is crucial. The right materials support safety and stability. According to industry reports, scaffolding needs to withstand forces up to 4,000 pounds in heavy-duty setups. Misjudgment in load capacity can lead to catastrophic failures. Always check specifications. Understanding what your project requires is vital.

Durability is another key factor. Steel and aluminum are popular choices, but their longevity varies. While steel exhibits strength, it can corrode over time. Aluminum is lighter, but it may not hold up under extreme loads. In a recent study, over 30% of accidents stemmed from material failure. Regular inspections are necessary to ensure safety.

Consider environmental factors too. Moisture and temperature fluctuations affect scaffolding materials. For instance, aluminum scaffolds may offer better performance in humid conditions. Assess the unique demands of your job site. Often, using the right components leads to fewer issues down the road. Choose wisely, keeping safety and project requirements at the forefront.

When assembling scaffolding for your project, choosing the right accessories and tools is crucial. You need to ensure safety and efficiency. Select guardrails that meet safety standards. They keep workers safe from falls. Different projects may require different heights. So, measure your needs carefully.

Tips: Always check for any visible damage on scaffolding parts. A small crack could lead to accidents. Regular inspections can prevent costly mishaps.

Consider using adjustable base plates. They offer stability on uneven surfaces. Stability is key for safety. Don’t overlook the importance of proper connectors. They should be sturdy to hold the structure together. Misaligned connectors can weaken the setup. This mistake can have serious consequences.

Tips: Use a checklist before starting your project. It helps you ensure you have all necessary parts. Missing even one item can cause delays and increase risk. Keep communication open among your team. Everyone must understand the importance of correct installation. A mistake during setup can influence the entire project.

When selecting scaffolding parts for a project, supplier reliability is crucial. Without dependable suppliers, delays can occur. Delays can lead to increased costs and project complications. Therefore, it is essential to research potential suppliers. Look for reviews and feedback from past clients. A reputable supplier should have a track record of timely deliveries.

Cost-effectiveness also plays a significant role. While it’s tempting to choose the cheapest options, this might lead to poor quality. Low-quality materials can cause safety hazards. Additionally, you may face constant repairs or replacements. Balancing cost with quality is vital. Consider long-term benefits over immediate savings. Sometimes, investing a little more upfront pays off in the end.

Consider verifying the supplier’s credentials. Check their certifications and safety records. This can build confidence in their reliability. Furthermore, make sure they offer good customer service. Communication is essential when issues arise. Remember, a good supplier will support you throughout your project, not just during the sale.