+86 18531742341

+86 18531742341

Leave Your Message

In the realm of construction, the choice of materials plays a pivotal role in ensuring safety and efficiency on job sites. One critical component that often goes overlooked is the scaffold plank, a vital element that supports workers and equipment at heights. According to industry reports from sources such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI), the proper selection of scaffold planks can significantly impact both safety and productivity, reducing accidents and project delays. It has been estimated that inadequate scaffold support systems are responsible for approximately 50% of all scaffolding-related injuries, underscoring the importance of choosing high-quality materials.

The selection of the right scaffold plank involves consideration of several factors including material type, load capacity, and compliance with safety standards. For instance, wood, metal, and composite materials each offer distinct benefits and challenges. Data from the Scaffold & Equipment Manufacturers Association (SEMA) indicates that nearly 80% of construction accidents can be traced back to improper use or inadequate maintenance of scaffolding systems. Understanding the specifications and limitations of scaffold planks is essential for project managers aiming to mitigate risks and enhance workforce safety. By prioritizing informed decisions in scaffold plank selection, construction teams can ensure a more secure and productive work environment.

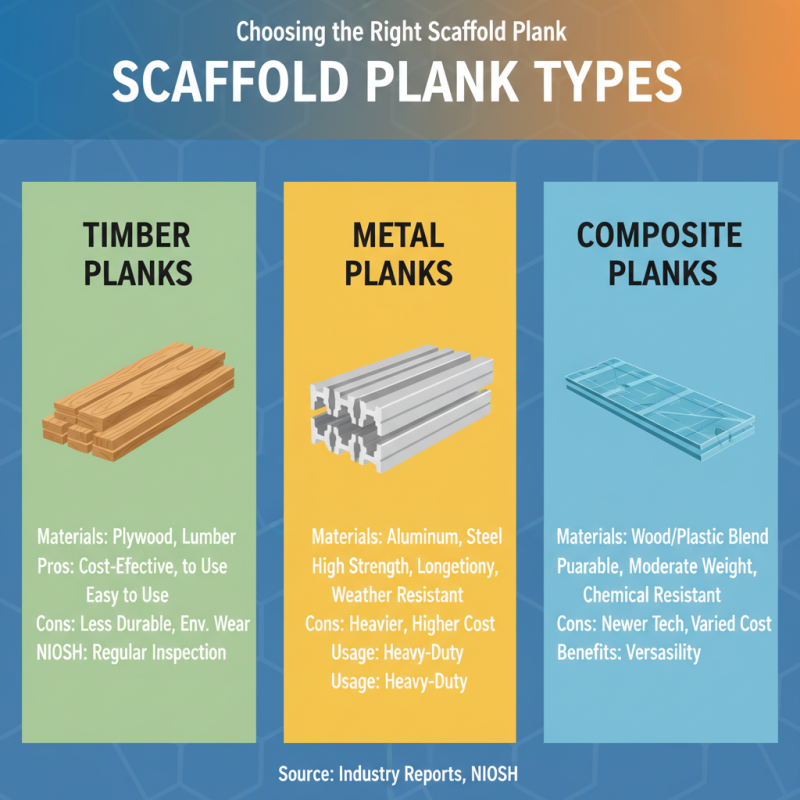

When choosing the right scaffold plank for a construction project, understanding the various types and materials is crucial. Scaffold planks can be broadly categorized into timber, metal, and composite materials, each with specific characteristics that cater to different construction needs. According to industry reports, timber planks, often made from high-quality plywood or lumber, are favored for their cost-effectiveness and ease of use. However, they may be less durable and can suffer from environmental wear. The National Institute for Occupational Safety and Health (NIOSH) suggests that timber planks should be inspected regularly for structural integrity, particularly in outdoor conditions.

Metal planks, often constructed from aluminum or steel, offer greater strength and longevity compared to their timber counterparts. They can support heavier loads and withstand harsh weather conditions, making them ideal for demanding construction sites. The Construction Industry Institute (CII) has reported that metal scaffolding can increase worksite safety and efficiency due to its robustness and ability to be quickly assembled and disassembled. Composite materials, on the other hand, which blend plastic and wood fibers, provide resistance to moisture and don’t splinter, enhancing safety for workers. Their increasing popularity can be attributed to advancements in material technology, promoting a balance between weight, strength, and safety.

Choosing the appropriate scaffold plank depends not only on the specific requirements of the project but also on the anticipated environmental conditions, weight loads, and safety regulations that must be adhered to. By understanding the advantages and limitations of each type, project managers can make informed decisions that promote both efficiency and worker safety on-site.

When selecting scaffold planks for a construction project, evaluating load capacity and adhering to safety standards are crucial for ensuring worker safety and project success. Load capacity refers to the maximum weight that a scaffold plank can support without the risk of failure. It's essential to consider not only the weight of the individuals working on the scaffolding but also the materials and tools that will be used. Different types of scaffold planks have varying load capacities, typically influenced by their material composition, thickness, and overall design. Proper calculations based on expected loads will help in identifying the right plank that can safely support the required weight.

In addition to load capacity, safety standards are vital in maintaining a secure working environment. Industry regulations dictate specific requirements for scaffold materials, including compliance with codes that govern strength, stability, and durability. Regular inspections of scaffolding equipment, including planks, are essential to detect any signs of wear or damage. Choosing planks that meet recognized safety standards minimizes the risk of accidents and enhances the overall trust in the construction process. By prioritizing load capacity alongside safety compliance, construction managers can ensure a reliable and safe work platform for their teams.

This chart compares the load capacities of various scaffold plank materials. Timber typically has a load capacity of 600 lbs, while aluminum and steel offer higher capacities of 1000 lbs and 1200 lbs respectively. Composite materials fall in the middle with a capacity of 800 lbs. Understanding these differences is crucial for ensuring safety and compliance in your construction projects.

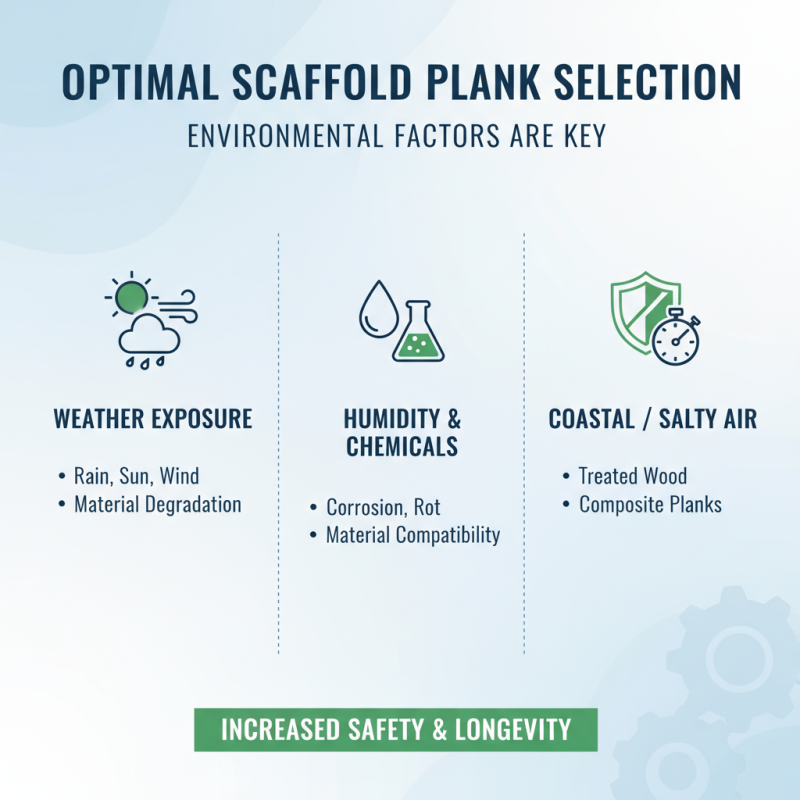

When selecting the right scaffold plank for your construction project, assessing environmental conditions is crucial. Factors such as weather exposure, humidity levels, and potential chemical interactions can significantly affect the choice of materials. For instance, if your project is located in a coastal area with high salt exposure, it's essential to consider planks made of treated wood or composite materials that offer enhanced durability and resistance to corrosion. The longevity of your scaffold system will directly impact safety and efficiency on the job site.

Tips: Always examine local climate conditions before deciding on materials. For example, in wet environments, opt for planks that are specifically designed to handle moisture without warping. Additionally, evaluate the likelihood of extreme temperatures that may cause certain materials to become brittle over time.

Durability should also factor into your decision-making process. Scaffold planks must withstand the weight of workers and materials while maintaining structural integrity throughout the project. If your project requires supporting heavy loads or involves abrasive environments, consider using planks crafted from sturdy materials such as aluminum or high-grade plywood. These options not only provide better strength but also offer a longer lifespan.

Tips: Regularly inspect scaffold planks for signs of wear and replace them as necessary to ensure safety. Implementing a routine maintenance check can help identify potential weaknesses early, keeping your construction project running smoothly.

When selecting a scaffold plank for your construction project, understanding the dimensions—length, width, and thickness—is crucial. The length of the plank not only determines how far it spans between supports but also affects its overall stability. For tasks that require extensive reach, longer planks might be necessary, but they should be evaluated against the ability to safely handle the load and the potential for bowing under pressure.

Width is also an important consideration. A wider plank offers more surface area for workers and materials, enhancing safety and efficiency on the job site. Conversely, if the width is too great for the intended application, it could make handling and transport more cumbersome. The thickness of the plank influences its load-bearing capacity. Thicker planks generally support heavier loads, but it’s essential to balance thickness with the overall weight considerations of the scaffolding system, as excessive weight can complicate both setup and stability.

By carefully evaluating these dimensions, you can ensure that the chosen scaffold plank meets the specific demands of your construction project while adhering to safety standards.

When selecting the right scaffold plank for your construction project, compliance with local regulations and codes is paramount. Each region may have specific requirements regarding the materials, dimensions, and load capacities of scaffolding components to ensure safety and structural integrity on job sites. Therefore, it is essential to familiarize yourself with the building codes applicable in your area before making any purchasing decisions. Failure to adhere to these regulations can not only compromise safety but can also lead to legal issues and project delays.

In addition to understanding local regulations, it’s important to ensure that the scaffold planks meet industry standards for quality and safety. This includes checking for certifications that indicate the planks have undergone rigorous testing for durability and load-bearing capacity. Consulting with local construction authorities or industry experts can provide valuable insights into the best practices for scaffold plank selection, ensuring that your choices align with established safety protocols. Moreover, regular inspections and maintenance of scaffold components during the project will help uphold compliance and protect the well-being of all site personnel.