+86 18531742341

+86 18531742341

Leave Your Message

In the construction industry, choosing the right scaffolding pipe is crucial for project safety and efficiency. Recent reports highlight that nearly 33% of workplace accidents result from inadequate scaffolding setups. According to industry expert Dr. James Wilson, "The quality of scaffolding pipes directly impacts worker safety." This underscores the importance of selecting appropriate materials.

The market offers various scaffolding pipe options. Each type has distinct benefits and challenges. For instance, galvanized steel pipes are known for durability but can be heavier to transport. Conversely, aluminum pipes are lighter but may not provide the same strength. As projects scale, these choices can significantly affect logistics and safety.

Contractors often feel overwhelmed by available options. Ensuring the right scaffolding pipe can make or break a construction timeline. Reflection on this choice is essential. A contractor's decision can influence not just the cost but also worker safety and project success. Understanding these dynamics is key to making an informed choice.

Scaffolding pipes are essential in the construction industry. They provide support and stability during building projects. Various materials are used, including steel and aluminum. Each type has unique benefits, impacting safety and cost-effectiveness.

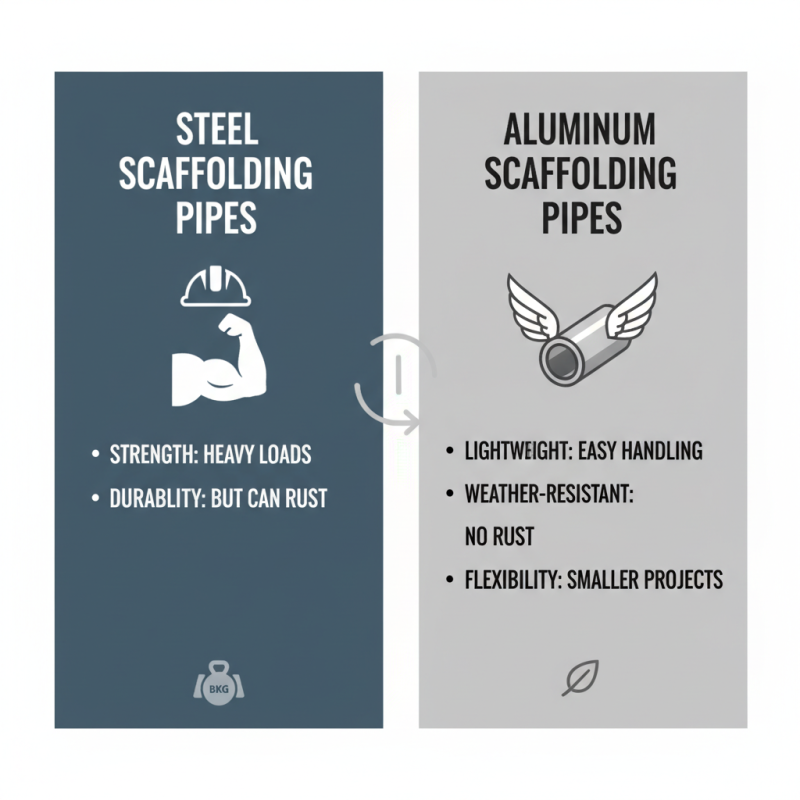

Steel pipes are very strong and can withstand heavy loads. They’re often used for larger projects but can be heavy and rust-prone. Aluminum pipes, on the other hand, are lighter and resistant to corrosion. However, they may not support as much weight as steel. Deciding which pipe type to use depends on project specifics.

Different diameters and lengths are available. It's important to choose the right dimensions for stability. A poorly planned scaffolding system can lead to accidents. Inspecting pipes regularly is crucial for safety. Construction sites can be unpredictable, so adaptability is key. Relying solely on one pipe type may not be the best approach; a mix might serve better. Consider your needs carefully.

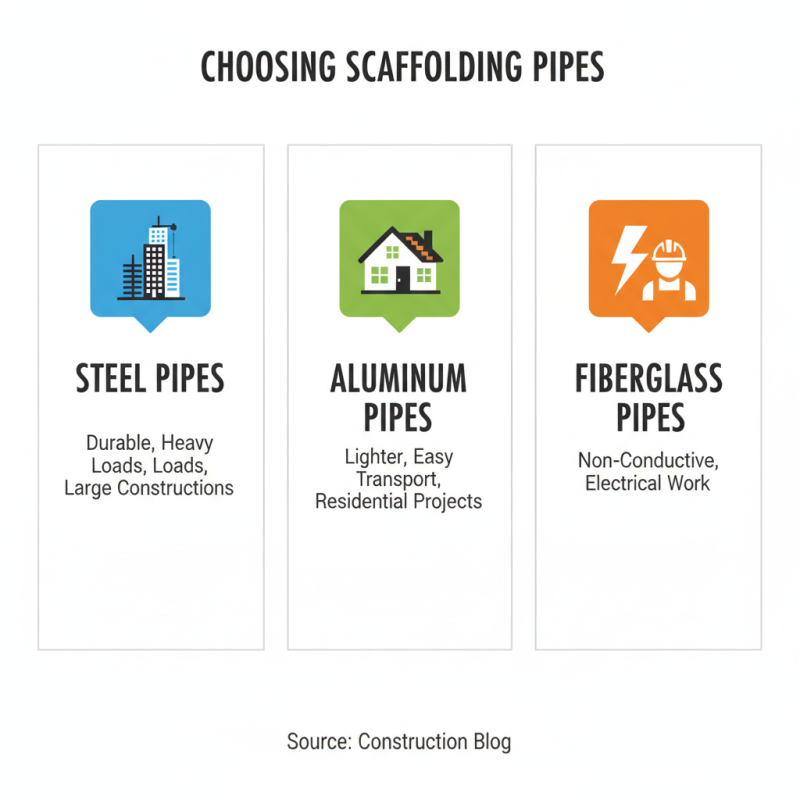

When choosing scaffolding pipes, consider the various types available. Steel pipes are durable and can handle heavy loads, making them ideal for large constructions. Aluminum pipes are lighter and easier to transport, suitable for residential projects. There are also fiberglass options, useful in electrical work due to their non-conductive properties.

Tips: Always check the weight capacity of a scaffold. Ensure it meets safety standards. Inspect pipes for any signs of wear before use. It’s essential to evaluate your project requirements carefully before selecting the appropriate type.

Another type is plastic scaffolding, which offers flexibility but lacks the strength of metal options. It’s best for short-term projects. While more affordable, plastic might not withstand heavy weather conditions. Additionally, consider the environment where the scaffolding will be used.

Tips: Keep an eye on the weather forecast. Unexpected rain can affect safety. Always have backup plans to ensure worker safety on site. Reflect on the materials that best suit your needs; sometimes, choices can be overwhelming.

When selecting scaffolding pipes, several key factors come into play. Material choice is crucial; options include steel, aluminum, or fiberglass. Steel pipes provide strength but add weight. Aluminum is lighter, yet may not support heavy loads. Fiberglass offers corrosion resistance but lacks strength compared to steel. Each option serves different construction needs.

Another factor is the pipe diameter. Standard sizes range from 1 inch to several inches wide. The diameter will affect load capacity and stability. A larger diameter may support heavier loads but can be cumbersome. Additionally, consider the height of your scaffolding. Taller structures require more robust pipes for safety.

**Tips:**

Always check for any visible damage or rust before use. Consistently inspect your scaffolding to ensure it meets safety standards. Ensure proper fittings and supports are used to enhance stability. Regular maintenance can prevent accidents and prolong the lifespan of your equipment.

Additionally, think about how easy the pipes are to transport and assemble. Improperly chosen pipes can lead to inefficiency and potential safety risks. Evaluate your project’s specific requirements, including load and duration. This reflection will aid in making an informed decision.

When choosing scaffolding pipes for construction, the material matters greatly. Steel and aluminum are the two main options. Steel is known for its strength. It can support heavy loads, making it suitable for large projects. However, steel is heavier and can rust if not protected. This maintenance requirement can be a drawback in some cases.

On the other hand, aluminum scaffolding pipes are lightweight and easy to handle. They are resistant to corrosion, which is a big plus in wet environments. Yet, aluminum may not bear as much weight as steel. For smaller projects, this might not be an issue. Still, relying solely on aluminum can be a risky choice in demanding conditions.

Deciding between these materials involves weighing the pros and cons. Think about the project type. Cost is also a factor. Steel may be cheaper initially but may incur extra maintenance costs. Aluminum can have a higher upfront cost, but long-term savings might balance it out. Consider these details before making a choice.

Scaffolding is crucial for construction safety. It's essential to follow safety standards and regulations. The Occupational Safety and Health Administration (OSHA) sets strict guidelines. According to OSHA, about 60% of construction injuries result from falls. A solid scaffolding pipe system can mitigate these risks.

Pipe materials play a significant role in safety. Steel and aluminum are commonly used. A report from the National Institute for Occupational Safety and Health (NIOSH) shows that proper material choice reduces accidents by nearly 30%. Regular inspections are vital. Visual checks can catch defects early.

Training workers on scaffolding safety is equally important. Many workers lack adequate training. Studies indicate that around 50% of accidents happen due to improper use. Incorporating hands-on training can improve awareness. Safety should always be a priority.