+86 18531742341

+86 18531742341

Leave Your Message

When it comes to construction safety and efficiency, "Ringlock Scaffolding Stairs" play a vital role. John Smith, a leading expert in scaffolding systems, emphasizes, "The right scaffolding can make or break a project’s success." These stairs are designed for stability and ease of use, making them essential in various construction environments.

In 2026, several advancements in Ringlock Scaffolding Stairs are expected. Enhanced materials promise increased durability, while improved design enhances safety measures. However, experts warn that not all products are equal. In fact, poor quality can lead to significant hazards on-site. Contractors must understand what to look for.

Attention to detail is crucial. Confirming the structural integrity of the stairs should be a priority. Regular inspections are necessary, yet many overlook this step. As projects evolve, so do safety requirements. Staying informed about these changes is essential for maintaining a safe work environment.

Ringlock scaffolding stairs provide safe and reliable access for construction sites. They offer a stable platform for workers and materials. These stairs are versatile, adapting to various construction environments. Their modular design lets them fit different heights and layouts. This adaptability can sometimes lead to assembly challenges. Proper training is vital to ensure safety and efficiency.

Understanding the structure of Ringlock stairs is crucial. Each component interlocks securely. The stairs feature non-slip surfaces to enhance safety. However, users must be cautious of wear and tear over time. Regular inspections are essential to maintain structural integrity. An overlooked issue could lead to unsafe conditions, requiring immediate attention.

The ability to customize these stairs stands out. Builders can adjust their height and width as needed. Still, this flexibility might result in mismatching parts if not properly checked. Workers might face difficulties when assembling or disassembling. It’s important to emphasize the importance of following guidelines closely. That will ensure a smoother construction process.

When considering Ringlock scaffolding stairs, several key features stand out. These stairs provide excellent stability and durability. Made from high-quality materials, they are designed to withstand heavy loads. The modular design allows for easy transportation and assembly. Users appreciate the lightweight components, ensuring that workers can set up quickly and safely.

Another essential feature is the non-slip surface. This provides peace of mind for workers navigating different heights. It’s crucial for preventing accidents on-site. Additionally, these stairs often come with adjustable heights. This flexibility can accommodate various scaffolding setups, making them practical for diverse construction projects.

While these features enhance safety and convenience, challenges can arise. Misalignment during assembly may lead to unsafe conditions. Workers sometimes overlook the importance of checking connections between components. Regular inspections can help prevent potential issues. A culture of safety should always be prioritized on any construction site. Paying attention to these details ensures that Ringlock scaffolding stairs are both effective and reliable.

| Feature | Description | Benefits |

|---|---|---|

| Material | High-strength galvanized steel | Durability and corrosion resistance |

| Load Capacity | Up to 250kg per stair | Safe for heavy usage and multiple workers |

| Stair Width | 600mm | Provides ample space for safe transit |

| Assembly | Quick and tool-free assembly | Saves time and labor costs |

| Safety Features | Anti-slip treads and guardrails | Enhances worker safety during use |

| Versatility | Compatible with various scaffolding systems | Increases usability across projects |

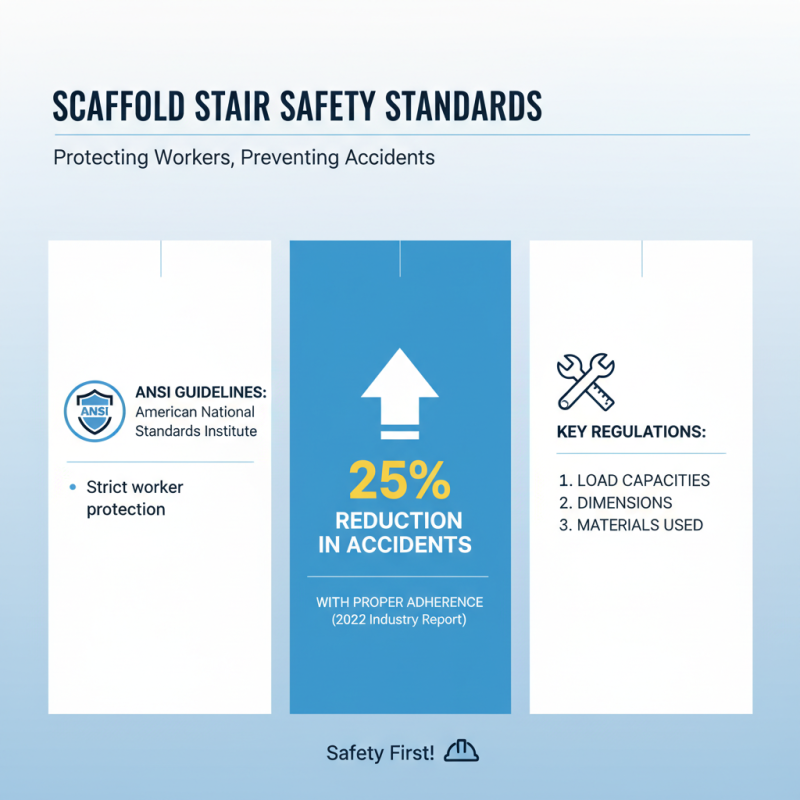

When considering scaffold stairs, safety standards are crucial. The American National Standards Institute (ANSI) outlines strict guidelines to ensure worker protection. According to a 2022 industry report, scaffold accidents can be reduced by 25% with proper adherence to safety regulations. These regulations cover load capacities, dimensions, and the materials used in scaffold stair construction.

One key detail is the minimum width for scaffold stairs. It must be at least 22 inches to accommodate workers effectively. Misconstruction or inadequate design can lead to dangerous situations. Poor maintenance of scaffold stairs can result in slips and falls, accounting for 15% of all scaffold-related injuries. Each company must prioritize the regular inspection of scaffolding equipment, including stairs, to meet compliance standards.

Interestingly, a survey indicated that 30% of workers felt unaware of the specific regulations regarding scaffold stairs. This highlights a significant gap in safety training. Employers need to provide comprehensive training sessions focused on these standards. Safety should always be a priority, but the industry still has a long way to go in implementing consistent training practices. Recognition of these gaps can lead to better safety measures and ultimately save lives.

When considering Ringlock scaffolding stairs, installation and maintenance are critical for ensuring safety. A report by the Scaffolding Industry Association states that improper installation can lead to a 30% increase in accidents on site. It’s essential to follow guidelines carefully to avoid mishaps. Checking alignment and securing each rung is vital during setup.

Regular maintenance checks are equally important. Wear and tear can diminish the structural integrity of scaffolding stairs. A study from the Occupational Safety and Health Administration (OSHA) indicates that regular inspections can reduce incidents by up to 50%. Inspect for rust, loose bolts, or any sign of damage. Remember, timely repairs can save lives.

Sometimes, workers overlook small details during inspections. A minor crack can escalate if ignored. Refreshing your knowledge on safety regulations is beneficial. Make sure that all workers are trained to recognize potential hazards. Clear communication about maintenance responsibilities can enhance overall safety on site.

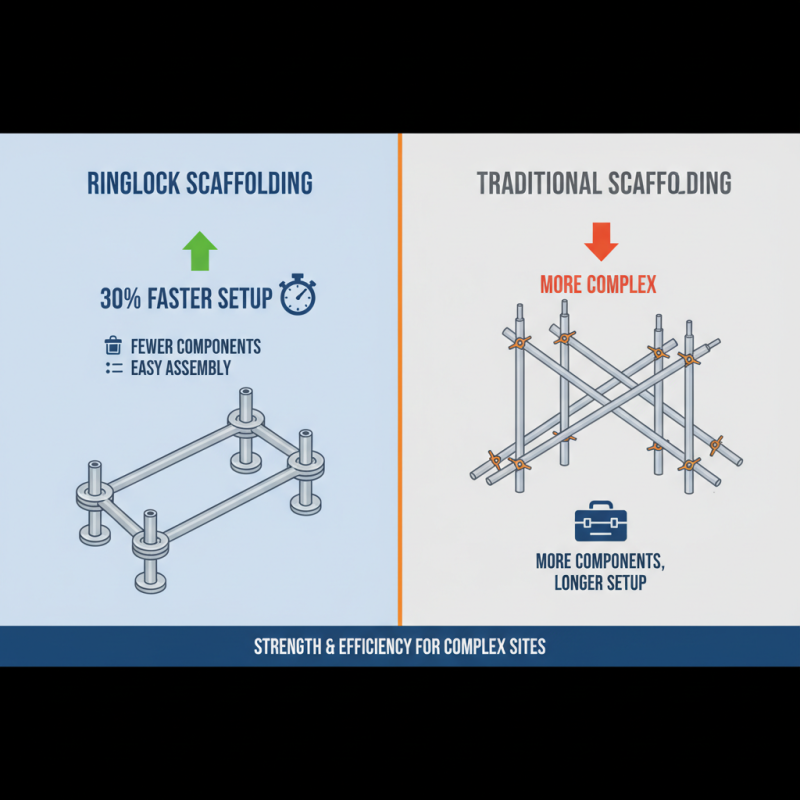

When considering scaffolding systems, Ringlock scaffolding stands out for its ease of assembly and strength. Unlike traditional systems, Ringlock uses fewer components. This reduces setup time significantly, leading to a 30% increase in efficiency, according to industry reports. This system is particularly advantageous in complex construction sites where time is of the essence.

Ringlock systems also offer greater adaptability compared to others. A recent study indicated that projects using Ringlock faced 20% fewer safety incidents. This is partly due to its robust locking mechanisms and enhanced structural integrity. In contrast, older scaffolding types lacked these critical safety features. However, it's important to note that initial costs may be higher, which can deter budget-conscious projects.

Tips: Ensure that your team receives proper training on assembly. This will enhance safety and avoid common mistakes. Investing in quality components can also make a substantial difference in longevity. Assessing your project needs critically will lead to more effective decisions on scaffolding choices. Remember, efficiency is key, but safety should never be compromised.