+86 18531742341

+86 18531742341

Leave Your Message

In the ever-evolving construction industry, choosing the right scaffolding is crucial. Cuplock scaffolding stands out for its versatility and strength. Industry expert John Smith, a renowned engineer, once stated, "Cuplock scaffolding is a game-changer for efficiency." His observation highlights the essential role this system plays in modern construction.

Cuplock scaffolding offers ease of assembly and disassembly. Workers can quickly set it up, saving valuable time on site. Its unique design allows for various configurations, accommodating different construction needs. However, some may overlook proper safety measures during installation. This oversight can lead to accidents and project delays.

While Cuplock scaffolding is highly regarded, it is not without its challenges. Knowing when and how to use it is key. Construction managers must remain vigilant about training their teams. This ensures that scaffold systems are used effectively and safely. It's a constant learning process, and reflection on past projects helps improve future practices.

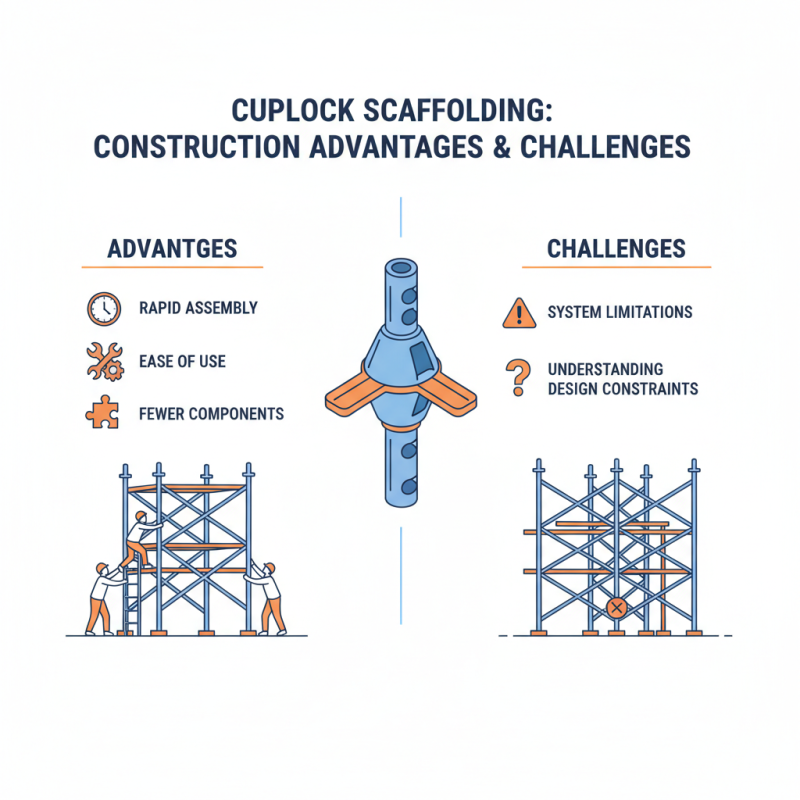

Cuplock scaffolding is a significant choice in the construction industry today. Its design allows quick assembly and disassembly. This saves valuable time on projects. Workers find the system easy to use. Fewer components mean less risk of losing parts. Yet, like any system, it has its challenges. Understanding the limitations is crucial.

One major advantage of cuplock scaffolding is its stability. The lock mechanism provides reliable support. This makes it suitable for various construction sites. Its versatility is appealing. However, it can be heavy. Handling heavier materials can pose an issue. Workers must be trained to manage loads safely.

Cuplock scaffolding offers significant advantages but also raises questions. Safety measures are vital. Workers need to be cautious about risks. Regular inspections are essential. They ensure the integrity of the scaffolding. The advantages may shine, but reflection is necessary. Find the balance between benefits and challenges.

When selecting cuplock scaffolding, key features play a crucial role in ensuring safety and efficiency on the construction site. The load capacity is paramount. A well-designed cuplock system can support up to 300 kg per square meter, making it suitable for various construction tasks. Durability also matters. Scaffolding should be made from high-quality steel to withstand harsh weather conditions.

Consider ease of assembly. A user-friendly design reduces setup time. Many reports suggest that faster assembly can improve productivity by up to 30%. Additionally, check for compatibility. Various scaffolding components should work seamlessly together. This flexibility can optimize the overall project efficiency.

Tips: Stay alert for any wear and tear on scaffolding components. Regularly inspect joints and locks. This practice enhances safety and may prevent costly accidents. Pay attention to the site environment. Heavy winds or rain can affect stability. Always prioritize safe working conditions.

Think about the storage options too. Bulky scaffolding can require significant space. Finding a system that folds efficiently or stacks can be beneficial. Scaffolding should not become an obstruction on the worksite. Adherence to these considerations ensures reliable and effective scaffolding setups.

| Model | Load Capacity (kN) | Weight (kg) | Material | Height (m) | Key Feature |

|---|---|---|---|---|---|

| Standard Cuplock | 50 | 15 | Steel | 2.0 | Easy Assembly |

| Heavy-Duty Cuplock | 75 | 20 | Aluminum | 2.5 | High Strength |

| Lightweight Cuplock | 30 | 10 | Steel | 1.8 | Portability |

| Versatile Cuplock | 60 | 17 | Steel | 2.2 | Adaptable Design |

| Economy Cuplock | 40 | 14 | Steel | 2.0 | Cost-Effective |

When considering cuplock scaffolding, various top brands and manufacturers emerge as industry leaders in 2026. These companies focus on innovation and safety. Their scaffolding solutions often prioritize ease of assembly and disassembly. Many construction projects benefit from the versatility of cuplock systems. They adapt well to various building sites, making them a popular choice.

However, not every option on the market meets high-quality standards. Some products may lack durability or stability. Users often discover that cheaper alternatives can lead to safety issues. It's essential to examine the materials used in manufacture and the design features of each system. This requires thorough research and understanding of potential limitations.

While leading brands are reliable, smaller manufacturers also provide unique options. Some of these niche players deliver cost-effective solutions with basic features. Users may find value in these approaches, but careful evaluation is needed. It's crucial to balance cost and quality to avoid making hasty decisions. Finding the right scaffolding is essential, but the decision-making process can be challenging.

When it comes to cuplock scaffolding, safety standards are non-negotiable. Compliance with local regulations ensures workers can perform their tasks without undue risk. The integrity of scaffolding structures is vital. Adequate inspections should happen before use. Look for signs of rust, damage, or wear.

Proper training for workers is essential. Everyone must understand how to install and dismantle scaffolding safely. Knowledge of load limits is crucial. Overloading can lead to catastrophic failures. Workers should also wear proper safety gear at all times.

Tips: Regular safety audits can reveal issues early. Create a checklist to streamline inspections. Encourage workers to voice concerns about safety. Open communication can prevent accidents. Moreover, a safety culture promotes accountability and diligence among the crew. Implementing these practices is not just about regulations; it’s about ensuring everyone goes home safe.

When selecting cuplock scaffolding for different construction projects, precision is crucial. Each project has unique requirements. For high-rise buildings, a more robust option is necessary. You want stability, ensuring worker safety at great heights. Lightweight options may suffice for smaller structures. They provide mobility and ease of assembly. However, there are trade-offs in strength.

The design of cuplock systems varies significantly. Some incorporate additional features for superior load-bearing capacity. Others focus on simple setups for quick installation. Reflecting on past projects, it's evident that a one-size-fits-all approach doesn't work. Factors like project duration and environmental conditions play a role. Consideration of these aspects enhances efficiency.

Cost is another critical consideration. While cheaper options may seem appealing initially, they can lead to issues down the line. Investing in quality can save money from repairs and delays. It's essential to evaluate the balance between cost and functionality carefully. Learning from past mistakes can guide better decision-making in the future.